What Are the Key Advantages of Using Aluminum Foil Breathable Gaskets in Sealing Applications?

- 1 Introduction

- 2 What Are Aluminum Foil Breathable Gaskets?

- 3 Applications of Aluminum Foil Breathable Gaskets in Industrial Settings

- 4 Applications of Aluminum Foil Breathable Gaskets in the Automotive Industry

- 5 Applications of Aluminum Foil Breathable Gaskets in Food Packaging

- 6 Performance Advantages of Aluminum Foil Breathable Gaskets

- 7 Comparison with Other Gasket Materials

- 8 Conclusion

Introduction

In the world of industrial sealing, automotive applications, and packaging solutions, materials must offer more than just durability. Aluminum foil breathable gaskets have emerged as a crucial component in various sectors, where the need for high-performance seals that combine both airtight and breathable properties is vital. These gaskets are a specialized form of sealing technology designed to provide a balance between preventing unwanted leaks while allowing controlled airflow through the seal.

Aluminum foil gaskets are often used in environments where traditional sealing materials fail to meet specific needs. The unique combination of aluminum’s strength and flexibility, coupled with the breathable properties of the material, makes it an ideal choice for a wide range of applications. Whether it’s in high-temperature industrial systems, automotive engines, or food packaging, the versatility of aluminum foil breathable gaskets offers a significant advantage in sealing performance.

What Are Aluminum Foil Breathable Gaskets?

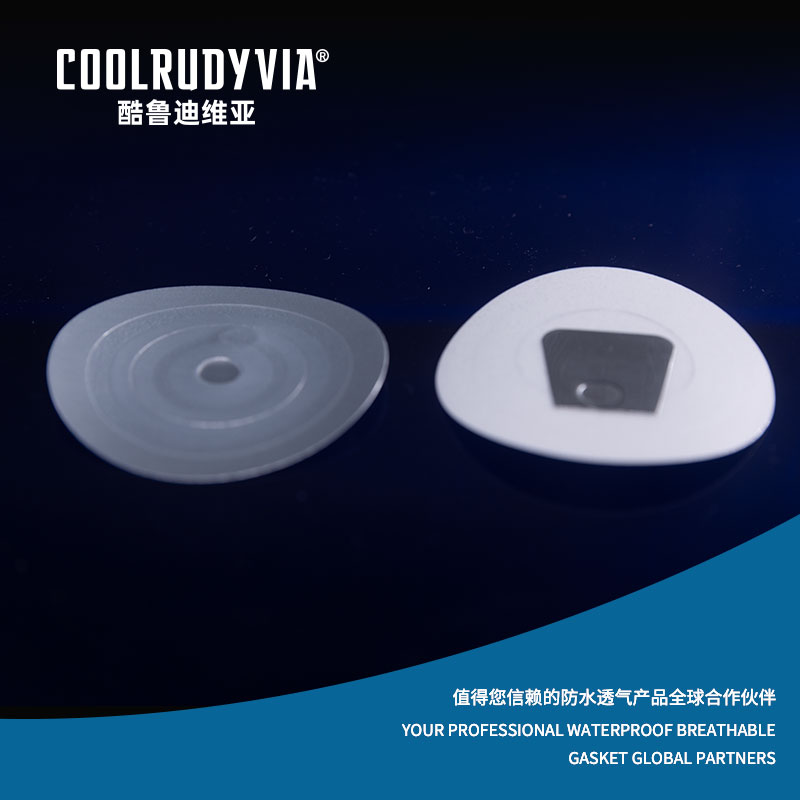

Aluminum foil breathable gaskets are a specialized sealing solution that combines the unique properties of aluminum foil with breathable materials, making them ideal for use in a variety of high-performance applications. These gaskets are designed to create airtight seals while allowing controlled airflow through their structure. This makes them particularly useful in environments where pressure regulation, moisture control, or the prevention of gas buildup is crucial.

Construction and Composition

The core material of these gaskets is aluminum foil, known for its strength, durability, and resistance to high temperatures. Aluminum is lightweight yet exceptionally strong, allowing the gasket to maintain its form under extreme conditions. The foil itself is often treated or coated to enhance its resistance to corrosion, wear, and degradation, making it suitable for harsh environments where traditional gaskets might fail.

The breathable aspect of these gaskets is achieved by incorporating microporous materials or structures into the aluminum foil. These materials are designed to allow air or gases to pass through the gasket while still preventing liquids or solid particles from leaking. This combination of aluminum foil and breathable materials offers a unique balance of protection, flexibility, and functionality.

Aluminum foil breathable gaskets can be manufactured in various shapes and sizes to meet the specific needs of different industries, with custom designs often being produced to fit particular machinery or applications.

Key Features

- Breathability: The microporous design of the gasket allows gases to pass through, while still sealing off liquids and solid particles.

- High-temperature resistance: Aluminum foil can withstand extreme temperatures, often up to 300°C, making these gaskets suitable for high-temperature environments.

- Corrosion resistance: Aluminum foil is naturally resistant to many types of corrosion, providing long-lasting durability even in harsh chemical or environmental conditions.

- Flexibility: Despite its strength, aluminum foil is flexible, allowing the gasket to conform to various shapes and surfaces, ensuring a secure seal.

Applications of Aluminum Foil Breathable Gaskets in Industrial Settings

In industrial applications, aluminum foil breathable gaskets play a vital role in ensuring the integrity and efficiency of various systems.

Pressure Vessel Sealing

Heat Exchangers and Boilers

Air Filtration Systems

Environmental Control Systems

Industrial Equipment Protection

Applications of Aluminum Foil Breathable Gaskets in the Automotive Industry

The automotive industry requires materials that can perform under extreme conditions. Aluminum foil breathable gaskets are ideal for these applications, offering reliable seals that allow for gas exchange without compromising performance. Here are some key uses in automotive systems:

-

Engine Components and Exhaust Systems

- Withstand high temperatures (up to 300°C).

- Provide a reliable seal in exhaust systems, preventing harmful buildup and maintaining engine efficiency.

- Allow gas release to prevent pressure buildup.

-

Automotive Battery Sealing

- Used in electric vehicles (EVs) to seal battery enclosures.

- Enable airflow for cooling and venting, preventing overheating.

- Prevent moisture buildup to protect battery components.

-

Air Intake and Filtration Systems

- Seal air intake systems while allowing clean, filtered air into the engine.

- Optimize fuel combustion and reduce emissions.

- Help maintain engine performance and meet environmental standards.

-

Seals for Automotive Lights and Electronics

- Protect electronic housings and lighting fixtures from moisture and dust.

- Ensure gases inside the components can escape.

- Prevent condensation, ensuring optimal performance and longevity of lights like LED headlamps.

Applications of Aluminum Foil Breathable Gaskets in Food Packaging

-

Extended Shelf Life and Freshness

- Controls oxygen and moisture to slow down spoilage.

- Helps preserve freshness for perishable items like fruits, vegetables, meats, and dairy.

- Regulates ethylene release to delay ripening in fresh produce, keeping it fresher longer.

-

Moisture and Gas Regulation in Vacuum Sealing

- Maintains vacuum while allowing controlled air passage.

- Helps regulate moisture and gas buildup inside the packaging.

- Essential for products like meats, cheeses, and ready-to-eat meals to prevent bacterial growth and maintain quality.

-

Controlled Atmosphere Packaging (CAP)

- Adjusts oxygen levels to slow down respiration and spoilage.

- Ideal for meat, fish, and packaged salads.

- Reduces the need for preservatives by controlling gas exchange, ensuring food freshness.

-

Packaging for Ready-to-Eat Meals

- Ensures optimal air exchange to prevent bacterial growth and maintain food integrity.

- Ventilates excess moisture and gases, preventing condensation.

- Extends shelf life and preserves taste and texture without artificial preservatives.

Performance Advantages of Aluminum Foil Breathable Gaskets

Aluminum foil breathable gaskets stand out due to their unique combination of properties, which make them ideal for a wide range of demanding applications. These gaskets provide multiple performance advantages over other sealing materials, making them a preferred choice in industries that require both airtight sealing and controlled breathability. Let’s explore the key performance advantages of aluminum foil breathable gaskets.

High-Temperature Resistance

One of the most significant benefits of aluminum foil breathable gaskets is their high-temperature resistance. Aluminum can withstand temperatures up to 300°C without losing its structural integrity, making it an excellent choice for environments with extreme heat, such as in industrial machinery, automotive engines, and exhaust systems.

In contrast, traditional gasket materials like rubber or silicone tend to degrade or lose their sealing properties when exposed to high temperatures for extended periods. This makes breathable aluminum gaskets particularly useful in applications where thermal stress is a constant factor.

Corrosion and Chemical Resistance

Another advantage of aluminum foil is its natural resistance to corrosion. Aluminum forms a protective oxide layer when exposed to air, which prevents further degradation. This is particularly important in industries where exposure to chemicals, moisture, or other corrosive elements is common, such as in the food processing, chemical manufacturing, and automotive sectors.

Many gasket materials, such as rubber or elastomers, are prone to chemical attack or environmental wear. In contrast, aluminum foil breathable gaskets maintain their sealing effectiveness even in harsh environments, providing long-lasting durability and reducing the need for frequent replacements.

Breathability and Moisture Control

The primary advantage of breathable aluminum gaskets is their ability to balance airtight sealing with breathability. These gaskets are designed to allow gases, moisture, or air to pass through the seal while blocking liquids or solid particles. This is crucial in applications where controlled air or gas exchange is necessary, such as in food packaging, battery enclosures, or medical equipment.

For example, in food packaging, the ability to regulate moisture is essential to prevent spoilage, mold growth, or condensation. The breathable nature of aluminum foil gaskets helps maintain the integrity of the sealed environment by allowing moisture to escape while keeping contaminants out.

Flexibility and Conformability

Despite being made of aluminum, which is typically considered rigid, breathable aluminum gaskets are flexible and can conform to a variety of surfaces. This flexibility ensures a secure seal even in situations where the surfaces to be sealed are uneven or irregular. The gasket material can bend and mold around contours, providing a tighter and more effective seal compared to some traditional gasket materials that may not conform as well.

This characteristic is particularly useful in industrial and automotive applications where components often have irregular shapes and require flexible seals that can adapt to their contours.

Lightweight and Durable

Aluminum foil is lightweight yet strong, making it an ideal material for applications that require both strength and ease of handling. The low weight of aluminum foil breathable gaskets reduces the overall weight of the system, which is particularly important in automotive and aerospace industries where weight efficiency is crucial.

In addition to being lightweight, aluminum foil is also durable, offering long-lasting performance even in challenging environments. This durability reduces the need for frequent replacements and maintenance, which can be costly and time-consuming.

Comparison with Other Gasket Materials

When selecting a gasket material for a specific application, it is important to compare the characteristics and advantages of various options.

| Property | Aluminum Foil Gaskets | Rubber Gaskets | Silicone Gaskets | Plastic-Based Gaskets |

|---|---|---|---|---|

| Temperature Resistance | Up to 300°C | Typically fails above 150°C | Up to 250°C | Up to 120°C |

| Chemical Resistance | High | Prone to degradation with chemicals, oils, and solvents | Moderate | Low to Moderate |

| Breathability | High – Allows controlled gas exchange | Low | Low | Low |

| Durability | High – Resistant to wear and corrosion | Moderate – May degrade in harsh conditions | Moderate – Not as durable in extreme conditions | Low – Can degrade from UV, chemicals, and extreme temperatures |

| Strength | High – Strong and robust | Moderate | Moderate | Low – Lightweight but lacks strength |

| Environmental Resistance | High – Resistant to UV, chemicals, and extreme temperatures | Low to Moderate | Moderate | Low – Prone to degradation |

Conclusion

Aluminum foil breathable gaskets offer unique advantages across a variety of industries, including automotive, industrial machinery, and food packaging. Their ability to balance airtight sealing with breathability makes them indispensable in applications where temperature resistance, moisture control, and long-term durability are critical.

English

English 中文简体

中文简体 Español

Español عربى

عربى