How to Precisely Select Aluminum Foil Seal Liners for Different Containers (PET/PE/PP/Glass) to Ensure 100% Seal Rate?

The Principle of Material Compatibility

The core of achieving a 100% seal rate lies in the "homogenous fusion" principle. The heat seal layer of the Aluminium Foil Seal Liner must be chemically compatible with the container material. When the induction sealing machine generates an electromagnetic field, the aluminum foil heats up rapidly, melting the underlying sealant layer to fuse it with the bottle mouth. If the materials do not match, issues such as weak bonding or easy peeling will occur.

- PET Containers: Require a sealing layer specifically designed for Polyethylene Terephthalate, commonly used in beverages and food.

- PE/PP Containers: Polyethylene (PE) and Polypropylene (PP) are sensitive to induction temperature and pressure; a sealant layer with a matching molecular structure is required to ensure a strong bond.

- Glass Containers: Glass surfaces are smooth and non-polar, necessitating an aluminum foil coated with specialized polymer resins to ensure excellent adhesion.

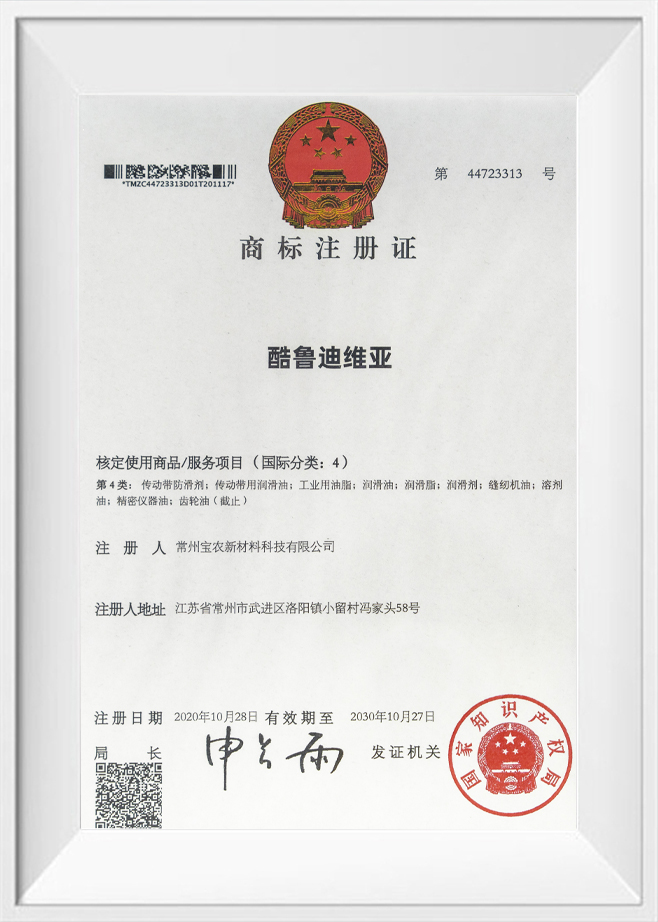

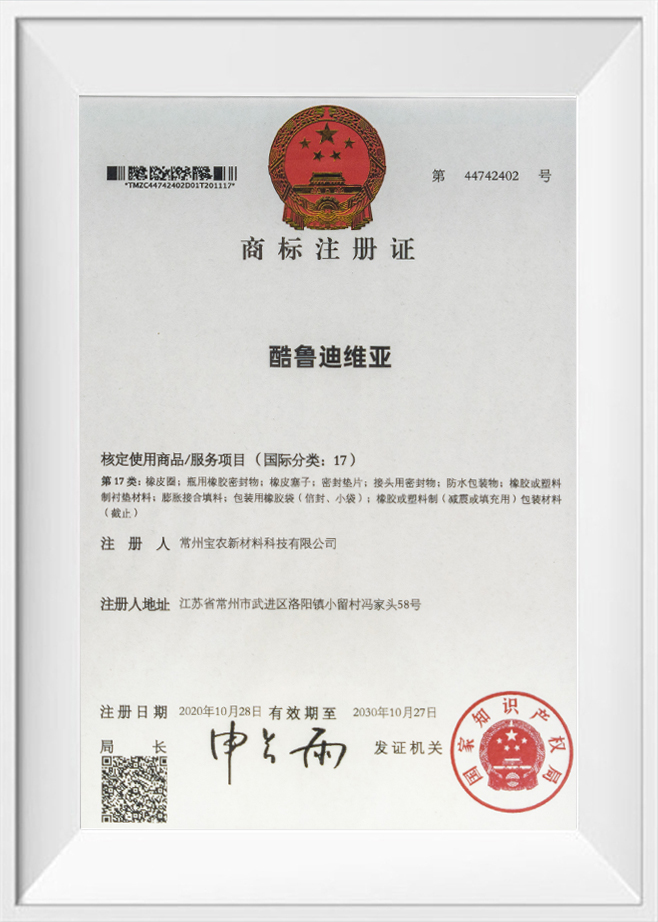

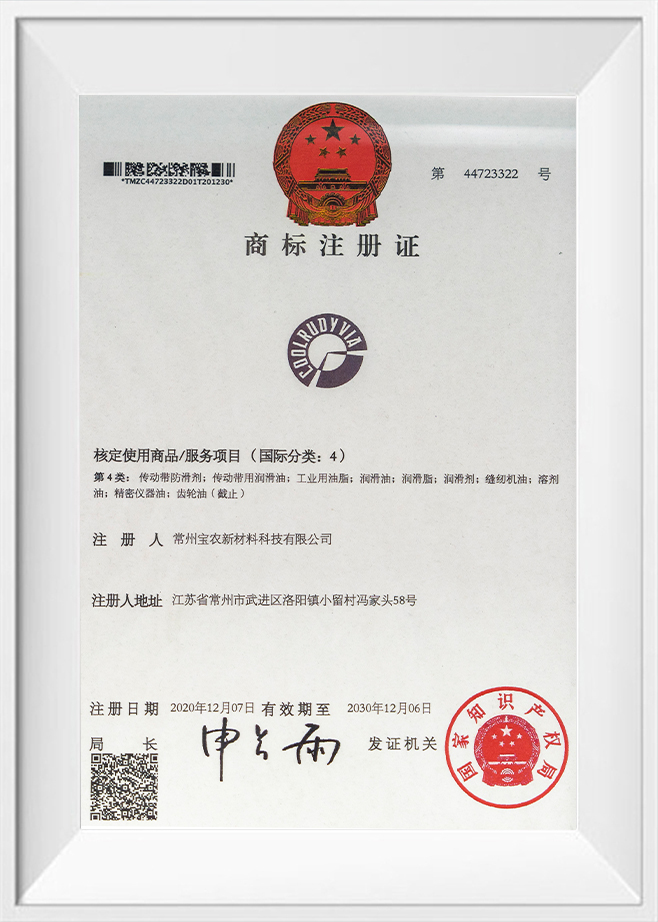

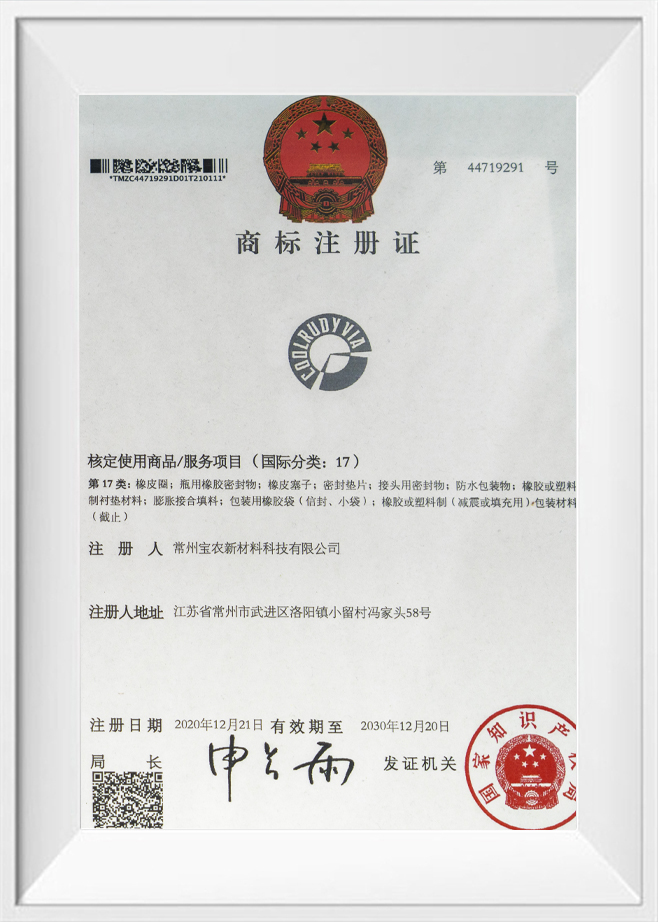

Changzhou Baonong New Material Technology Co., Ltd. has eight years of deep expertise in the field of precision sealing. Located in Changzhou ("Dragon City"), the company operates a standardized industrial workshop of over 6,000 square meters. We apply the same rigorous approach to material science from our waterproof and breathable membranes to our high-performance sealing liners. Our products are widely used in beverages, pesticides, and specialty chemical packaging, ensuring 100% sealing safety under various transportation conditions.

Parameter Comparison Table for Different Container Materials

When selecting a liner, please refer to the following core parameters based on the container material:

| Container Material | Heat Seal Layer Material | Recommended Temp | Sealing Performance | Application Industry |

| PET | Special PET Sealant | 160°C - 200°C | High barrier, high peel strength | Beverages, Soy Sauce, Pharma |

| PE (HDPE/LDPE) | PE Homogeneous Film | 150°C - 180°C | Acid/Alkali resistant, tough | Pesticides, Detergents, Milk |

| PP | Modified PP Resin | 170°C - 210°C | High temperature stability | Canned food, High-heat Chemicals |

| Glass | Polymer Functional Coating | 180°C - 220°C | Superior surface adhesion | Cosmetics, Condiments |

| Universal | Multi-layer Composite | 160°C - 190°C | Broad compatibility | Lab supplies, Mixed production lines |

Frequently Asked Questions (FAQ)

Q1: Why do some aluminum foil seals fail during mass production?

Sealing stability depends on equipment precision and liner consistency. Changzhou Baonong New Material Technology Co., Ltd. is equipped with more than 90 sets of automated equipment with independent intellectual property, enabling high-speed, precise, and stable mass production. Every liner undergoes a dual mechanism of "automated equipment testing + manual inspection" to ensure minimal dimensional errors and uniform coating. Combined with our "breathable + sealed" integrated solutions, our liners maintain a 100% leak-proof seal even under complex pressure fluctuations caused by temperature changes.

Q2: How do aluminum foil liners resist corrosion from aggressive pesticides or chemicals?

For chemically aggressive contents, a simple aluminum layer is insufficient. The R&D team at Changzhou Baonong New Material Technology Co., Ltd. is dedicated to product innovation in anti-corrosion and functionalization. Depending on the chemical properties of the contents (such as strong acids, bases, or volatile solvents), we add special protective coatings or functional films to the aluminum foil. This allows the liner to maintain excellent chemical resistance while providing "waterproof and breathable" features, ensuring safety throughout the product's shelf life.

Q3: How does your company help customers reduce the risk of seal selection during the R&D stage?

We adhere to the philosophy of "rooting in the present and grasping development trends." Changzhou Baonong New Material Technology Co., Ltd. provides more than just products; we offer an integrated process covering "design, R&D, production, and sales." In the early stages of product development, we conduct professional compatibility and pressure simulation tests based on the customer's bottle samples (PET/PE/PP, etc.). Leveraging our 6,000sqm factory capacity and 8 years of industry experience, we quickly provide high-quality, standardized custom solutions to help customers gain consumer trust.

How to Upgrade Coatings for Aluminum Foil Gaskets to Prevent Penetration and Oxidation in Volatile Solvent or Corrosive Pesticide Packaging?

The Challenge of Chemical Corrosion in Packaging

In the packaging of high-concentration pesticides or volatile organic solvents, a standard Aluminum Foil Gasket often faces severe challenges. Corrosive chemicals can react with the aluminum layer, causing "pitting corrosion" or oxidation, which leads to leakage and product degradation. To prevent the foil from being penetrated, the seal must be upgraded with high-performance functional coatings and specialized barrier films.

- Multi-Layer Composite Technology: By laminating specialized films such as PET, PEN, or fluorinated films onto the aluminum foil, a physical barrier is created that prevents direct contact between the corrosive chemicals and the metal.

- Corrosion-Resistant Primers: Upgrading to chemically inert resin coatings ensures that even if volatile gases penetrate the top layer, the adhesive bond remains intact, preventing delamination.

- Optimized Heat-Seal Polymers: Using modified polymers that are resistant to swelling when exposed to solvents ensures the integrity of the seal throughout the product's shelf life.

Changzhou Baonong New Material Technology Co., Ltd. has been committed to solving these complex packaging challenges since its establishment. Based in "Dragon City" (Changzhou), the company has spent eight years perfecting the design and R&D of high-end sealing and breathable products. With an industrial standard workshop exceeding 6,000 square meters, our team focuses on integrating advanced material science into our pesticide packaging and chemical series, ensuring that every seal is not just a closure, but a safety guarantee for transportation and storage.

Parameter Comparison: Standard vs. Enhanced Anti-Corrosive Gaskets

The following table illustrates the performance differences between standard liners and the upgraded solutions provided for harsh environments:

| Performance Feature | Standard Aluminum Foil Gasket | Enhanced Anti-Corrosive Version | Critical Benefit |

| Barrier Layer Material | Basic PE/PP Coating | PET/Fluorinated/Specialized Resin | Prevents chemical penetration to the foil |

| Solvent Resistance | Low (Prone to swelling) | High (Inert to most solvents) | Maintains seal integrity for 24+ months |

| Oxidation Prevention | Moderate | Excellent (Dual-surface protection) | Avoids "pinhole" corrosion in the aluminum |

| Thermal Stability | Standard | Enhanced (High-heat resistance) | Prevents seal failure during high-temp storage |

| Seal Strength | >10N/15mm | >18N/15mm | Higher security for dangerous goods |

Frequently Asked Questions (FAQ)

Q1: How does Changzhou Baonong New Material Technology Co., Ltd. ensure the consistency of these high-performance gaskets during mass production?

Precision is key when dealing with multi-layered protective coatings. Changzhou Baonong New Material Technology Co., Ltd. is equipped with more than 90 sets of independent intellectual property-owned automated equipment. These high-speed and precise machines ensure that the functional coatings are applied with absolute uniformity. Furthermore, each product undergoes a dual inspection mechanism—automated equipment testing combined with manual inspection—to ensure that the anti-corrosive properties are consistent across every batch, helping our customers gain the trust of global consumers.

Q2: Can these upgraded gaskets also provide breathable functions for pesticide packaging?

Yes. Many pesticides release gases that can cause "bloating" or "collapsing" of the container. Changzhou Baonong New Material Technology Co., Ltd. specializes in "breathable yet waterproof" integrated products. Our R&D team can combine high-performance anti-corrosive aluminum foil with breathable membranes. This integrated design allows for gas exchange while preventing the liquid from leaking, even if the contents are highly volatile or corrosive, ensuring safety in both use and transportation.

Q3: Why is Changzhou Baonong New Material Technology Co., Ltd. considered a leading choice for standardized chemical packaging solutions?

After eight years of rapid development, Changzhou Baonong New Material Technology Co., Ltd. has become one of the few standardized, modern, and high-quality integrated manufacturers in the industry. Our ability to handle the entire process—from design and R&D to large-scale production—allows us to offer customized solutions for various bottle types and chemical compositions. Our solid position in the industry is built on entrepreneurship and innovation, ensuring we provide fast, stable, and efficient high-quality products to the pesticide and beverage packaging sectors.

English

English 中文简体

中文简体 Español

Español عربى

عربى