What Are the Key Benefits of Using Aluminum Foil Gaskets in Sealing Systems?

Aluminum foil gaskets are critical components in sealing systems that require a combination of flexibility, durability, and protection against both moisture and air. These gaskets are made from high-quality aluminum foil that is often layered with materials designed for specific applications, providing unique sealing properties that cannot be replicated by standard gasket materials. In industries ranging from automotive manufacturing to packaging, aluminum foil gaskets have proven to be a vital element in ensuring reliability and safety.

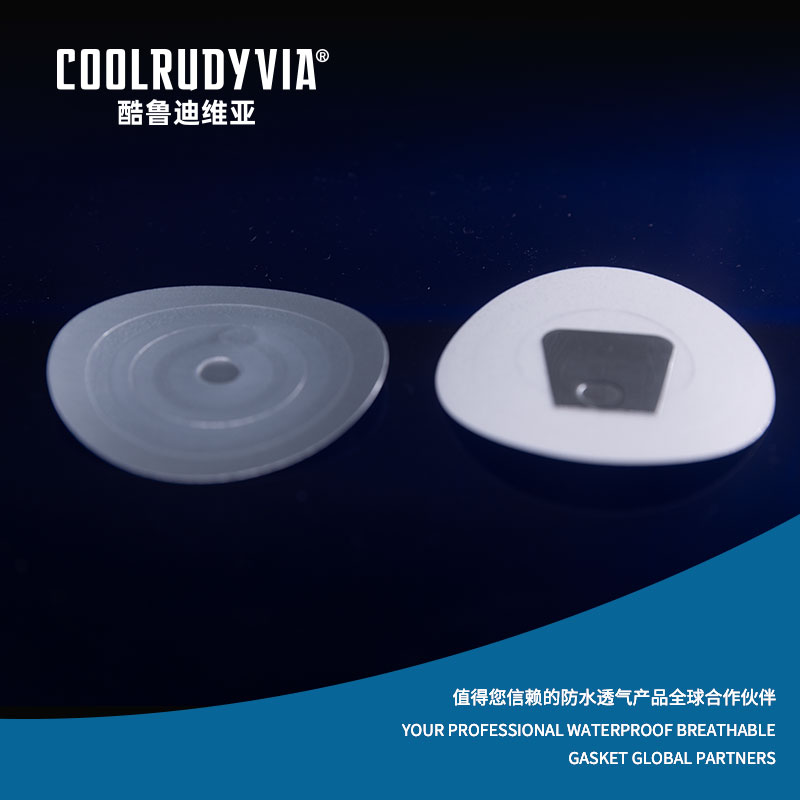

What Is an Aluminum Foil Gasket?

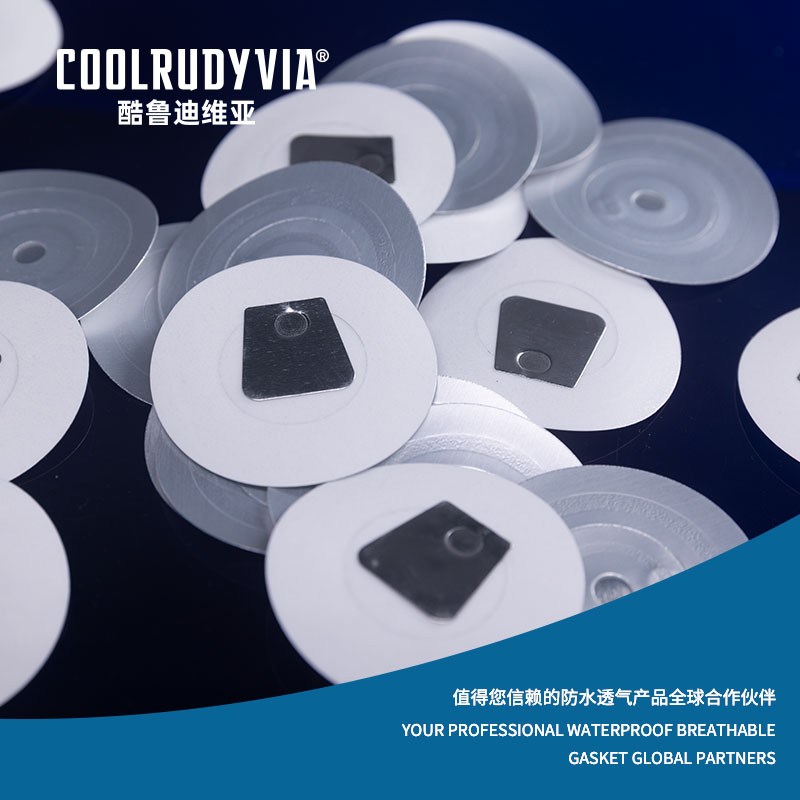

An aluminum foil gasket is a sealing product made from aluminum foil, typically combined with other materials, to create a versatile barrier. These gaskets are designed to prevent leakage, control pressure, and provide a reliable seal between two surfaces. Commonly used in applications where both waterproofing and breathability are essential, aluminum foil gaskets offer excellent performance in high-demand environments.

The unique properties of aluminum foil gaskets are derived from the aluminum's lightweight nature, resistance to corrosion, and excellent thermal conductivity. These gaskets are typically used in applications where sealing is critical to maintaining the integrity of the enclosed system, such as in automotive parts, beverage packaging, or industrial machinery.

Key Characteristics of Aluminum Foil Gaskets

- Durability: Aluminum foil gaskets are highly resistant to environmental factors such as moisture, temperature fluctuations, and chemical exposure, making them ideal for harsh conditions.

- Breathability: A significant advantage of aluminum foil gaskets is their ability to allow air or gas to pass through while preventing the leakage of liquids. This unique combination of breathability and waterproofing is crucial for applications in industries like food packaging, automotive, and electronics.

- Lightweight: Despite their robust properties, aluminum foil gaskets are lightweight, making them easy to handle and install without compromising on strength or functionality.

- Cost-Effectiveness: Compared to other advanced sealing materials, aluminum foil is relatively inexpensive, making aluminum foil gaskets a cost-effective option for manufacturers.

Applications of Aluminum Foil Sealing Liners

Aluminum foil sealing liners are widely used in various industries due to their unique properties. Below are some common applications:

1. Automotive Industry

In the automotive sector, aluminum foil sealing liners are commonly used in components such as headlamps, engine parts, and other assemblies that require a reliable seal. The ability of these gaskets to withstand high temperatures and provide an airtight seal makes them ideal for use in critical parts of vehicles.

2. Food and Beverage Packaging

In the food and beverage industry, aluminum foil sealing liners are used to seal containers, ensuring that they are airtight and leak-proof. These gaskets are particularly important in beverage packaging, where freshness and protection from contamination are paramount.

3. Pesticide and Chemical Packaging

The chemical industry, especially in the packaging of pesticides and other hazardous materials, benefits from the use of aluminum foil sealing liners. These gaskets prevent leakage and contamination, ensuring that dangerous chemicals are safely contained.

4. Electronics

In electronics, aluminum foil sealing liners are often used in enclosures and devices that require protection from moisture and dust. Their breathability allows for the ventilation of heat while keeping out harmful elements.

The Importance of Aluminum Foil Gaskets in Sealing Systems

Sealing systems are integral to the safety and efficiency of many products, and aluminum foil gaskets play a crucial role in maintaining their functionality. Here's why:

1. Prevention of Contamination

Aluminum foil gaskets effectively prevent contaminants such as dust, moisture, and gases from entering a sealed environment. This is essential in industries like food packaging, automotive, and electronics, where the integrity of the product must be preserved.

2. Enhanced Safety

The combination of breathability and waterproof properties of aluminum foil gaskets ensures that products remain safe for transportation and storage. In industries such as automotive and chemical packaging, these gaskets provide a barrier against the escape of potentially dangerous materials.

3. Improved Efficiency

By preventing leaks and maintaining pressure, aluminum foil gaskets help improve the overall efficiency of machinery and systems. In automotive engines or industrial equipment, gaskets ensure that components operate as intended, minimizing downtime and maintenance costs.

Choosing the Right Aluminum Foil Gasket

Selecting the appropriate aluminum foil gasket requires careful consideration of the specific needs of your application. Some of the factors to consider include:

- Material Composition: Aluminum foil gaskets can be made from various materials, depending on the desired properties. For example, adding a rubber or silicone layer can improve flexibility and compressibility, while enhancing the sealing properties.

- Temperature Resistance: Consider the operating temperature range of your application. Some aluminum foil gaskets are designed to withstand extremely high or low temperatures, making them suitable for a wide range of industrial uses.

- Environmental Resistance: Ensure that the gasket material is resistant to the chemicals, moisture, and other environmental factors it will encounter in the application.

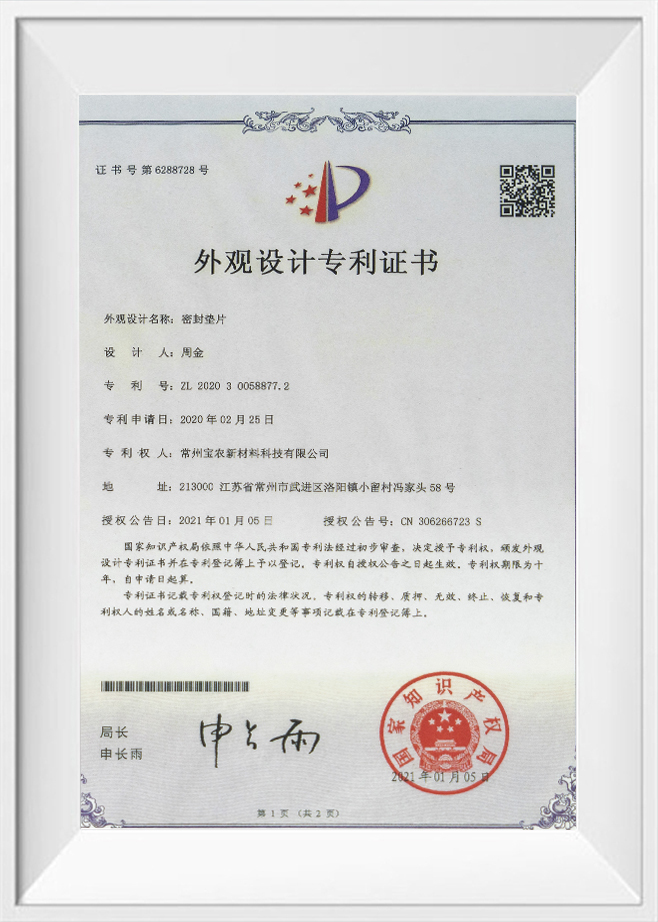

Changzhou Baonong New Material Technology Co., Ltd. is dedicated to providing cutting-edge sealing solutions, including aluminum foil gaskets. The company specializes in the design, research and development, and production of waterproof and breathable products such as gaskets, plugs, and covers. These products are widely used in automotive, beverage packaging, and pesticide packaging, among other industries.

Why Choose Baonong?

Expertise in Waterproof and Breathable Solutions

Baonong specializes in the design, R&D, and production of high-quality waterproof and breathable products such as gaskets, plugs, and covers. With years of industry experience, they understand the precise needs of various sectors, including automotive, packaging, and electronics.

State-of-the-Art Production Facilities

Baonong operates over 90 sets of proprietary automated equipment. These high-speed, precision machines ensure efficient, stable, and reliable production, resulting in top-tier products.

Commitment to Quality Assurance

Baonong uses a dual inspection process—combining automated equipment testing and manual checks—to guarantee product performance and safety. This ensures that every gasket, plug, or cover meets the highest standards before reaching customers.

Fast, Stable, and Efficient Service

With more than 8 years of experience and a 6,000㎡ production facility, Baonong's integrated approach to R&D, manufacturing, and sales allows them to respond swiftly to market demands, providing fast, stable, and high-quality products to clients.

Tailored Solutions for Diverse Needs

Baonong understands the unique requirements of different industries and can offer tailored solutions that meet specific sealing, waterproofing, and breathable needs. Their versatile products are ideal for critical applications such as automotive headlamps, beverage packaging, and pesticide packaging.

Aluminum foil gaskets are an essential component in many industries, offering a unique combination of breathability and waterproofing that makes them invaluable in sealing applications. Whether it's for automotive parts, food packaging, or electronic devices, these gaskets provide a reliable solution that enhances product safety, durability, and efficiency.

English

English 中文简体

中文简体 Español

Español عربى

عربى