How Does ePTFE Vent Membrane Enhance Product Durability and Performance?

What is ePTFE Vent Membrane?

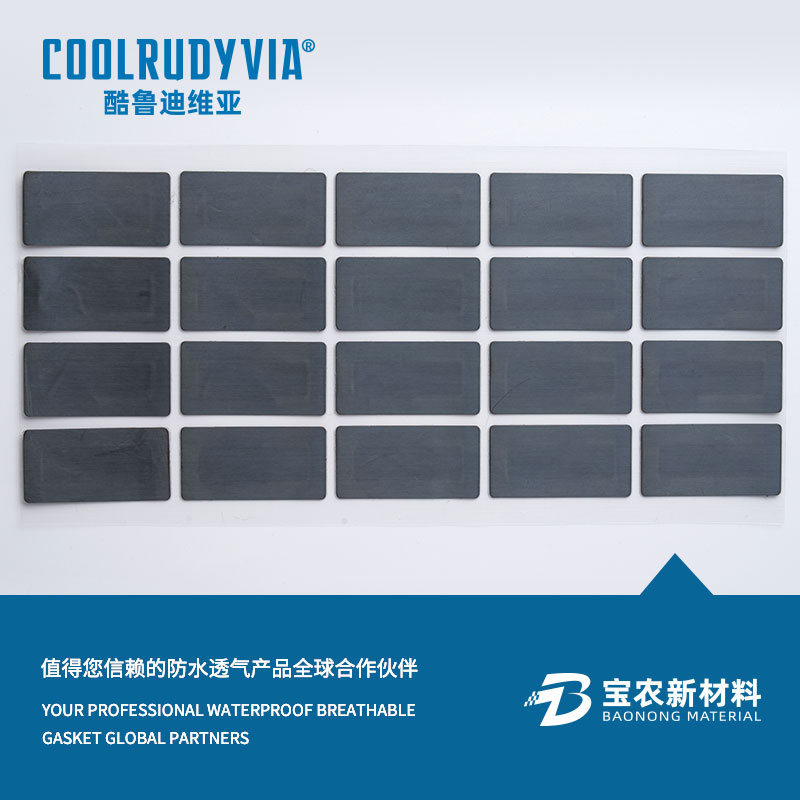

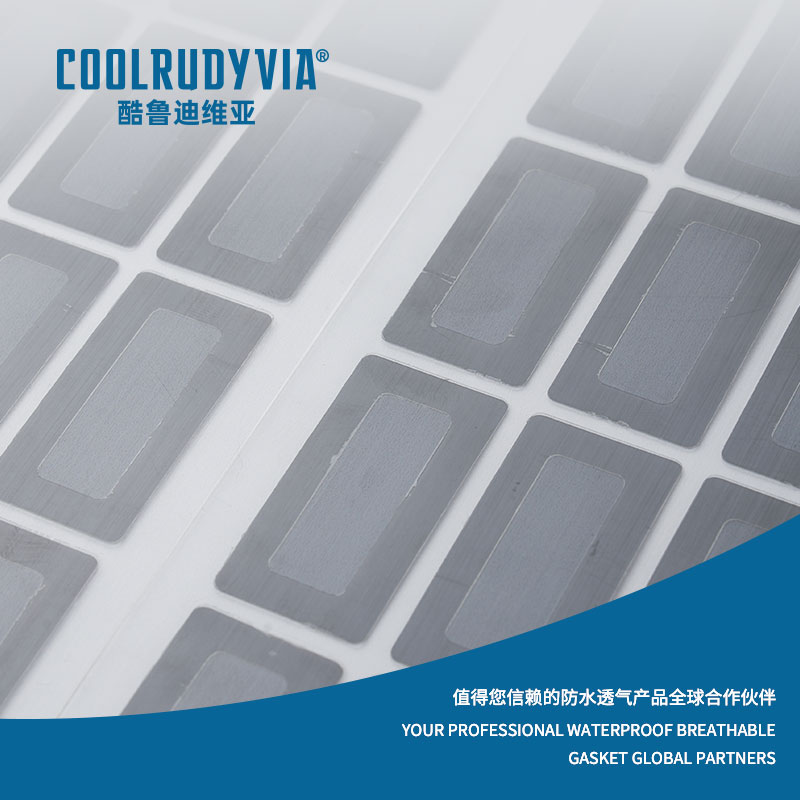

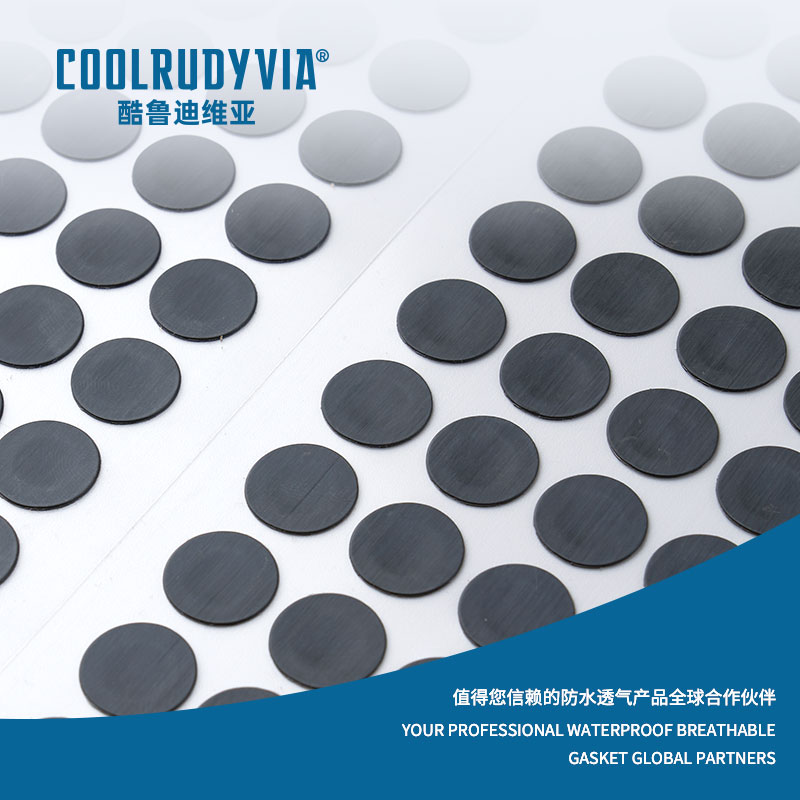

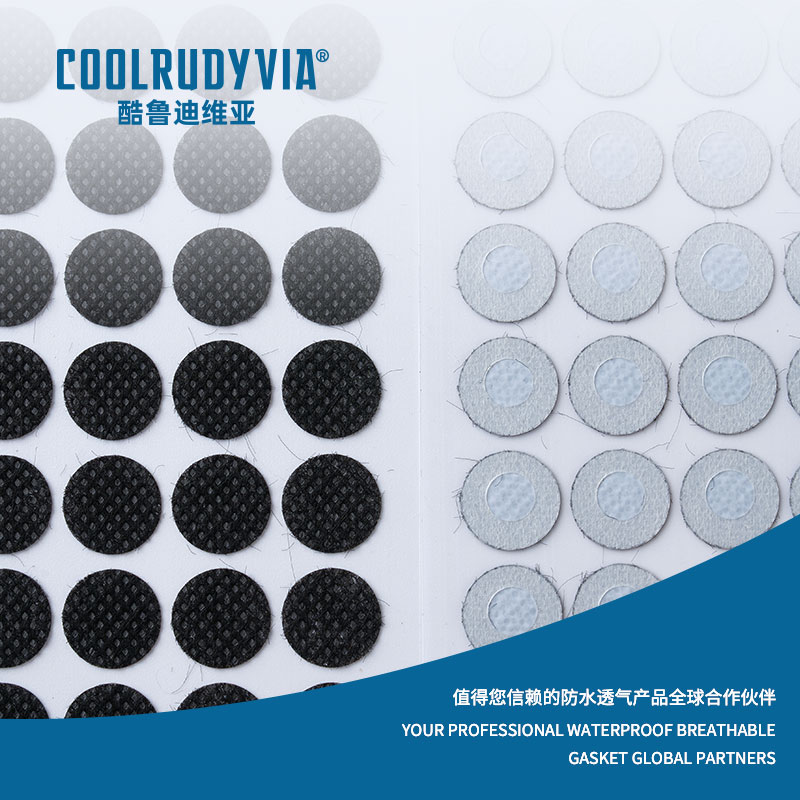

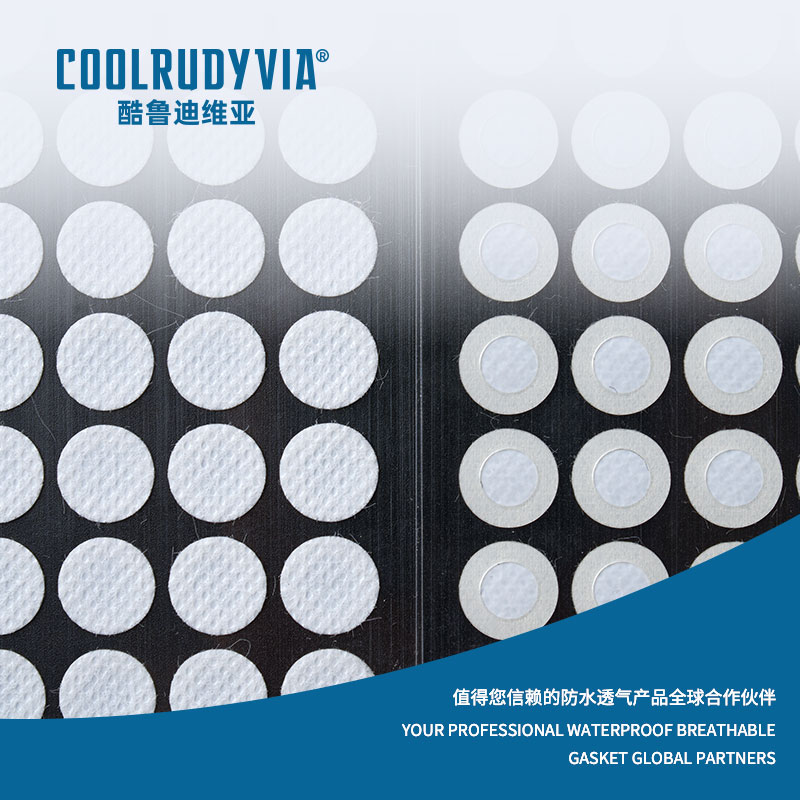

Expanded Polytetrafluoroethylene (ePTFE) is a specialized material known for its microporous structure that provides exceptional waterproofing while still allowing air and gases to pass through. ePTFE vent membranes are used to protect products from the damaging effects of moisture while allowing for the necessary ventilation that prevents pressure buildup or condensation.

ePTFE vent membranes are widely utilized in industries where moisture protection and air circulation are critical, such as in automotive headlamps, beverage bottle packaging, and pesticide packaging. The balance of breathability and waterproofness is essential to ensure product integrity during both use and transportation.

Structure and Composition of ePTFE Membranes

The unique properties of ePTFE are derived from its microstructure, consisting of micropores that are large enough to allow air and gas molecules to pass through but small enough to block water droplets. This configuration results in a material that is:

- Breathable: ePTFE allows air and moisture vapor to escape from the enclosed space.

- Waterproof: Despite being breathable, the micropores in ePTFE are small enough to prevent water ingress, making it ideal for sealing applications where moisture resistance is required.

- Durable: ePTFE is resistant to a wide range of chemicals and extreme temperatures, ensuring long-term reliability.

The structure of ePTFE can be manipulated during the manufacturing process to fine-tune its porosity, making it suitable for specific applications, from highly breathable membranes for packaging to waterproof vent caps used in automotive lighting.

Applications of ePTFE Vent Membranes

Automotive Headlamps

Automotive headlamps are exposed to extreme temperatures and environmental conditions, making moisture ingress a significant concern. ePTFE vent membranes are used in headlamp assemblies to ensure that condensation does not form within the lamp, while still allowing the internal components to “breathe.” This prevents fogging and protects against damage caused by temperature fluctuations.

Beverage and Food Packaging

Beverage and food packaging often require a balance between maintaining product freshness and allowing for air exchange. ePTFE vent membranes are commonly used in beverage bottles to allow the contents to “breathe” while keeping moisture out, ensuring that the packaging does not swell or degrade during storage or transportation.

Pesticide Packaging

Pesticide packaging needs to prevent moisture from entering while allowing air exchange to prevent pressure buildup. ePTFE vent membranes provide a reliable solution for keeping the contents dry and ensuring the packaging maintains its integrity under varying environmental conditions.

Electronics and Consumer Products

ePTFE vent membranes are used in electronic devices to allow heat dissipation and prevent condensation inside the device. Their ability to balance breathability and waterproofing ensures that electronic products can function optimally even in challenging environments.

Key Benefits of ePTFE Vent Membranes

Moisture Protection

The primary function of ePTFE vent membranes is to protect products from the damaging effects of moisture. By preventing water from entering sensitive areas, these membranes enhance the durability and reliability of products, especially in harsh or humid environments.

Pressure Equalization

ePTFE vent membranes are also crucial for maintaining pressure balance within enclosures. In sealed containers, internal pressure can build up due to temperature changes or gas expansion. The microporous structure of ePTFE allows air to escape, preventing pressure from reaching dangerous levels.

Enhanced Product Longevity

By preventing moisture buildup and maintaining stable internal pressure, ePTFE membranes help extend the lifespan of products. This is especially important in industries where product reliability is paramount, such as automotive and electronics.

Versatility

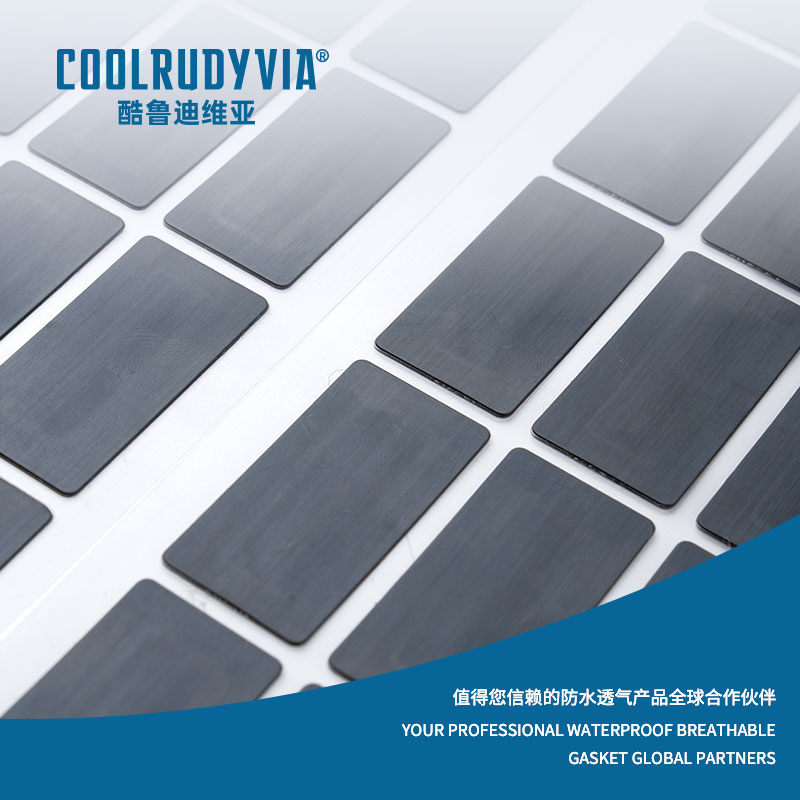

ePTFE vent membranes can be customized in terms of porosity and size to meet specific application requirements. This makes them highly versatile and suitable for a wide range of industries, from packaging to industrial equipment.

Environmental Benefits

ePTFE is a durable material that can withstand harsh environmental conditions, reducing the need for frequent replacements. Additionally, because ePTFE is chemically inert, it does not degrade or release harmful substances over time, making it a more environmentally friendly option compared to other materials.

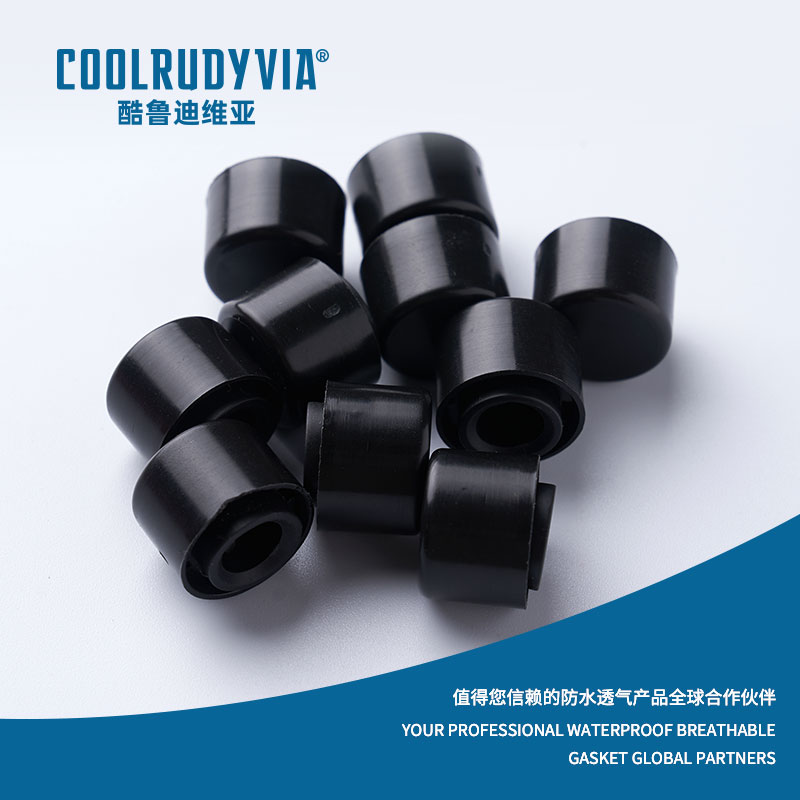

The Role of ePTFE Vent Caps in Product Integrity

ePTFE vent caps are often used as part of a larger sealing system to ensure the safety and integrity of packaged products or sensitive components. These caps provide an effective way to regulate the pressure and moisture levels within a container, preventing issues like swelling, leaks, or condensation.

Applications of ePTFE Vent Caps include:

- Waterproof and breathable enclosures for electronic devices

- Pressure relief for packaging materials

- Seals for automotive and industrial components

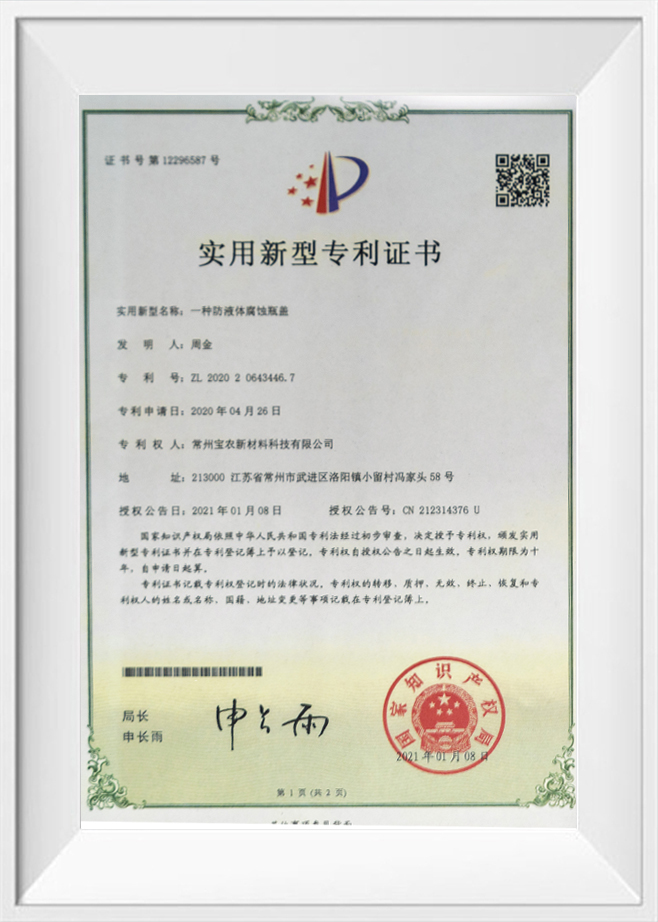

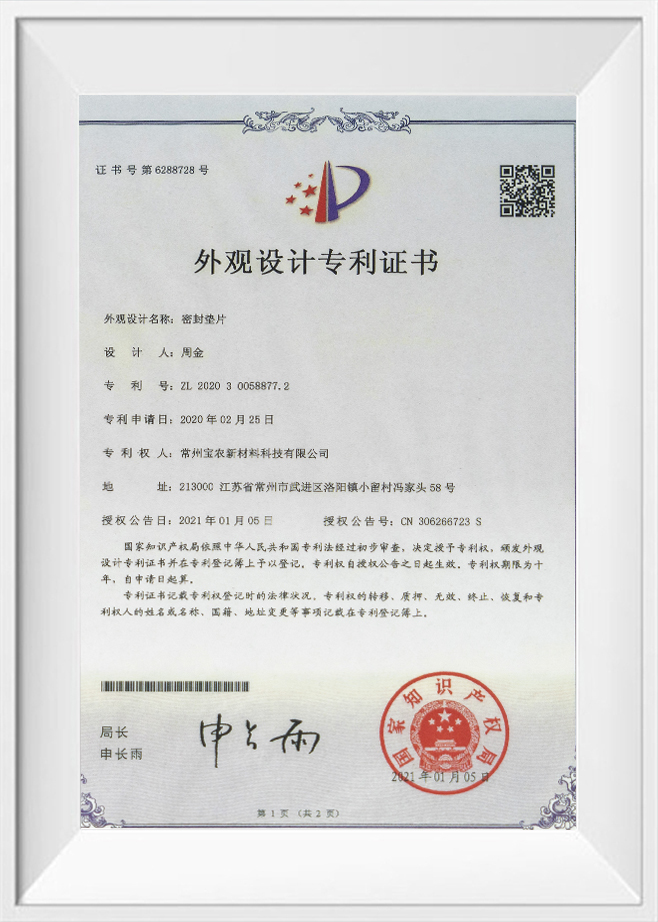

Changzhou Baonong New Material Technology Co., Ltd. is dedicated to designing and manufacturing a wide range of waterproof and breathable products, including ePTFE vent membranes and caps. With years of experience and a strong commitment to quality, Baonong’s products meet the high demands of various industries, including automotive, packaging, and electronics.

Baonong’s advanced automated equipment ensures that each ePTFE membrane and cap meets the stringent quality standards required for reliable and long-lasting performance. With a focus on both research and development and precision manufacturing, the company provides tailored solutions that meet the specific needs of their clients.

Conclusion

In summary, ePTFE vent membranes offer a unique solution for balancing breathability and waterproofing in a wide range of industries. From automotive headlamps to packaging, these materials provide essential protection against moisture and pressure buildup, enhancing the longevity and reliability of products. Changzhou Baonong New Material Technology Co., Ltd. is leading the production of ePTFE breathable membranes and breathable caps, providing customized solutions for diverse industry needs.

English

English 中文简体

中文简体 Español

Español عربى

عربى