What are the key considerations when choosing a waterproof breathable vent plug for automotive applications?

Introduction

In the world of automotive engineering, ensuring the durability and safety of components under varying environmental conditions is essential. One such component is the waterproof breathable vent plug. These devices, often used in automotive applications, provide crucial functions in maintaining the pressure equilibrium inside various sealed automotive components, such as headlamps, sensors, and electronics, while preventing contaminants like dust and water from entering.

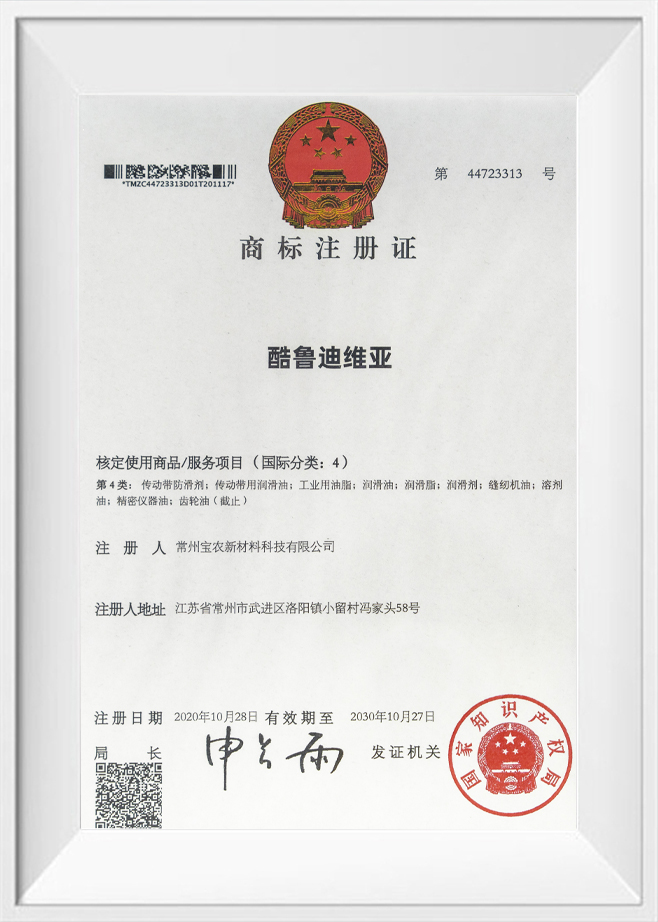

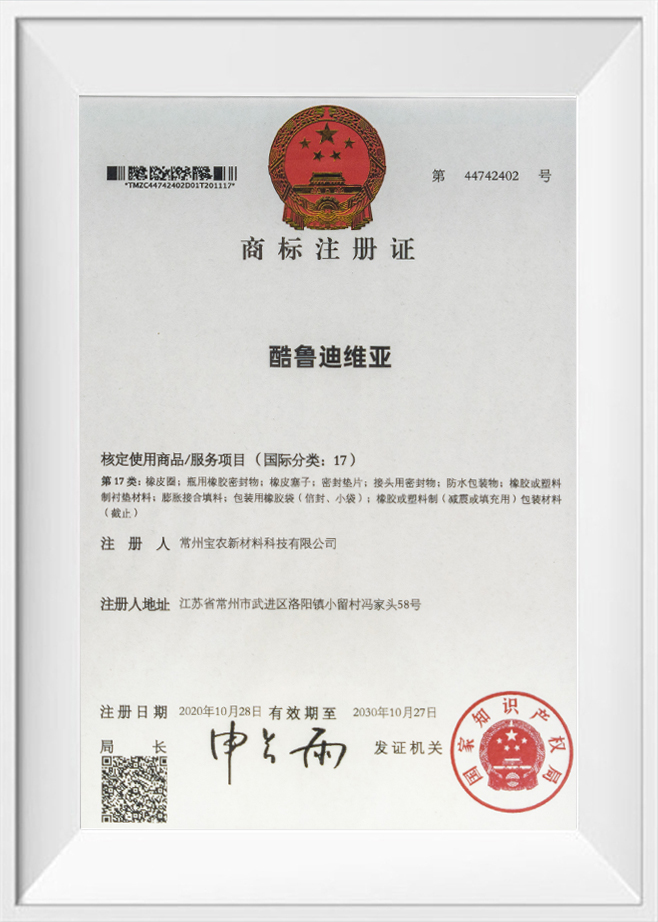

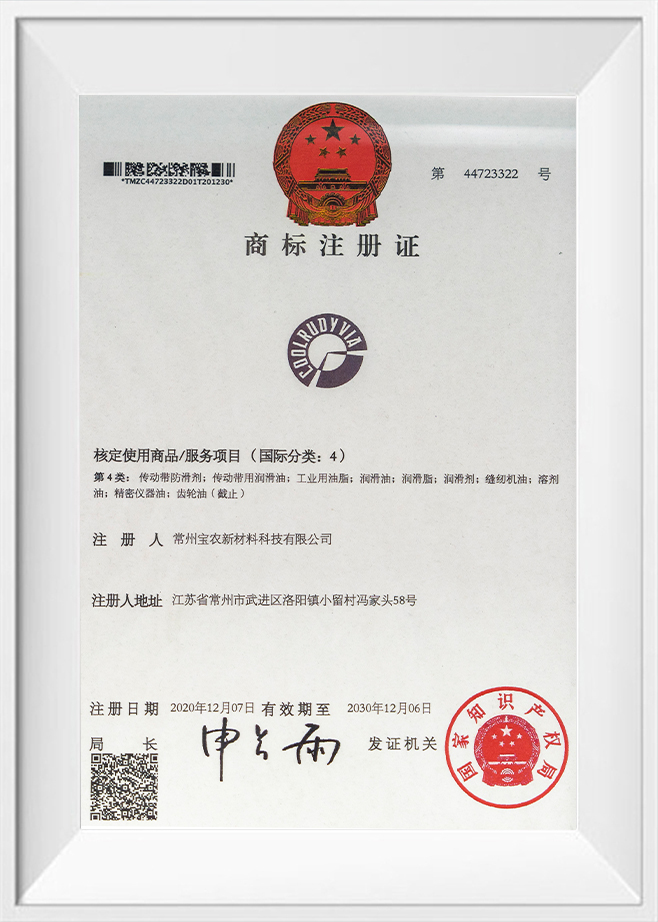

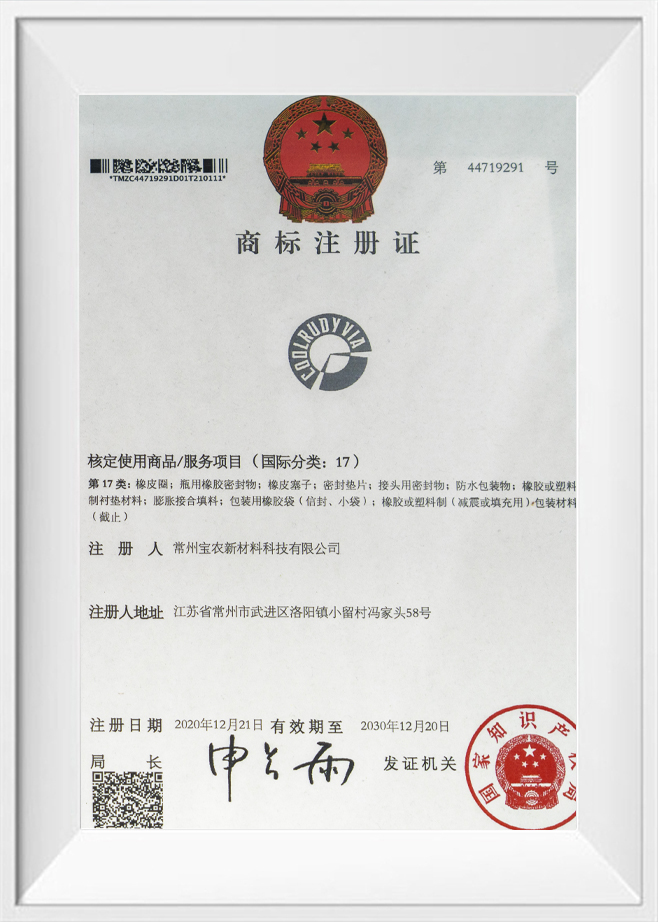

Changzhou Baonong New Material Technology Co., Ltd. is a key player in producing waterproof breathable vent plugs for a range of industries, including automotive. With over eight years of experience, the company has earned a strong reputation for its high-quality products and innovative solutions, particularly in the automotive sector, where moisture control and pressure regulation are critical.

I. What is a Waterproof Breathable Vent Plug?

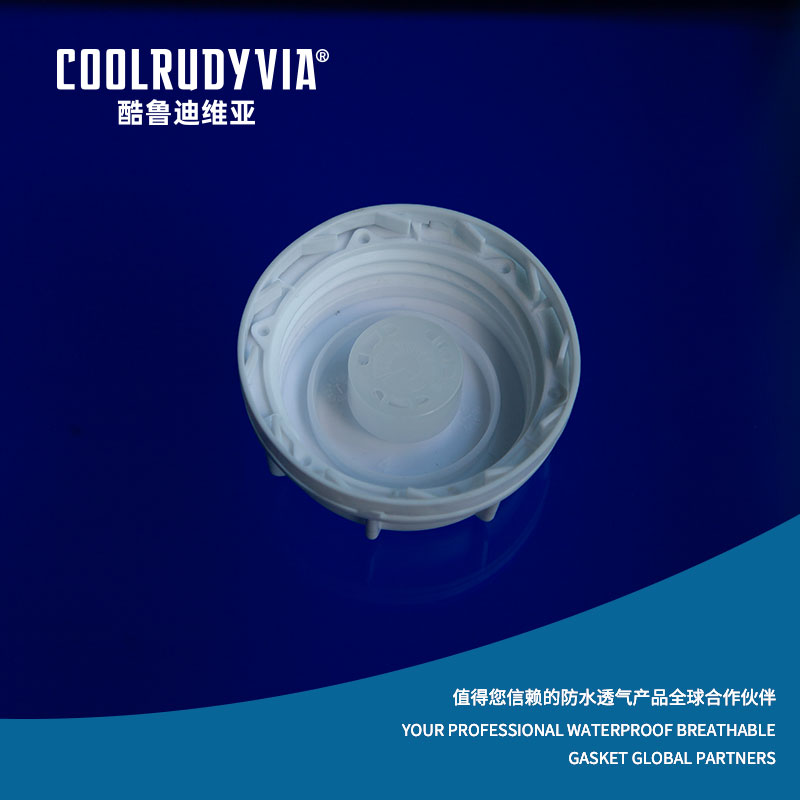

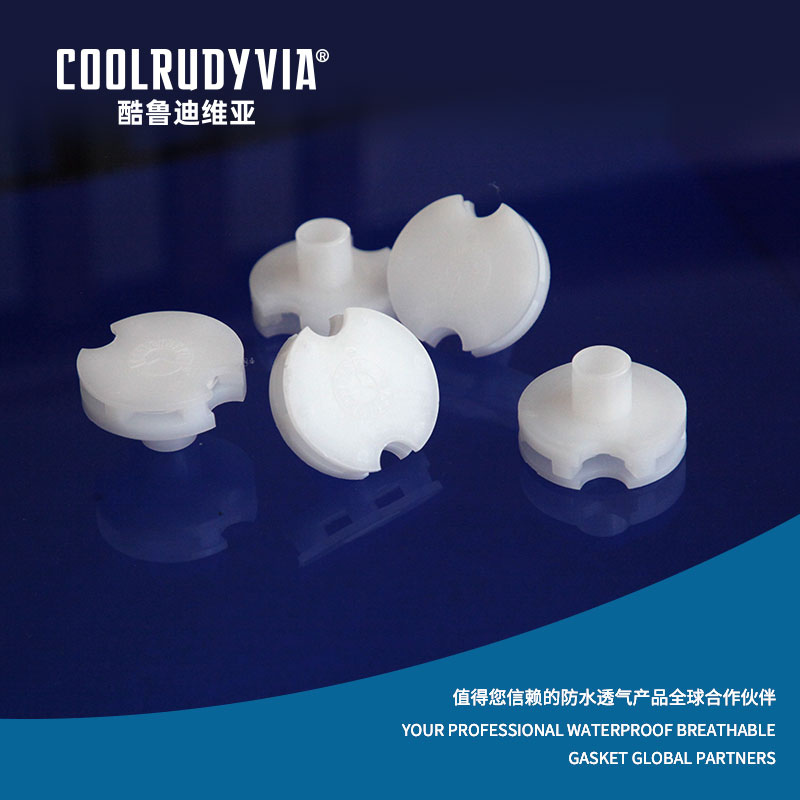

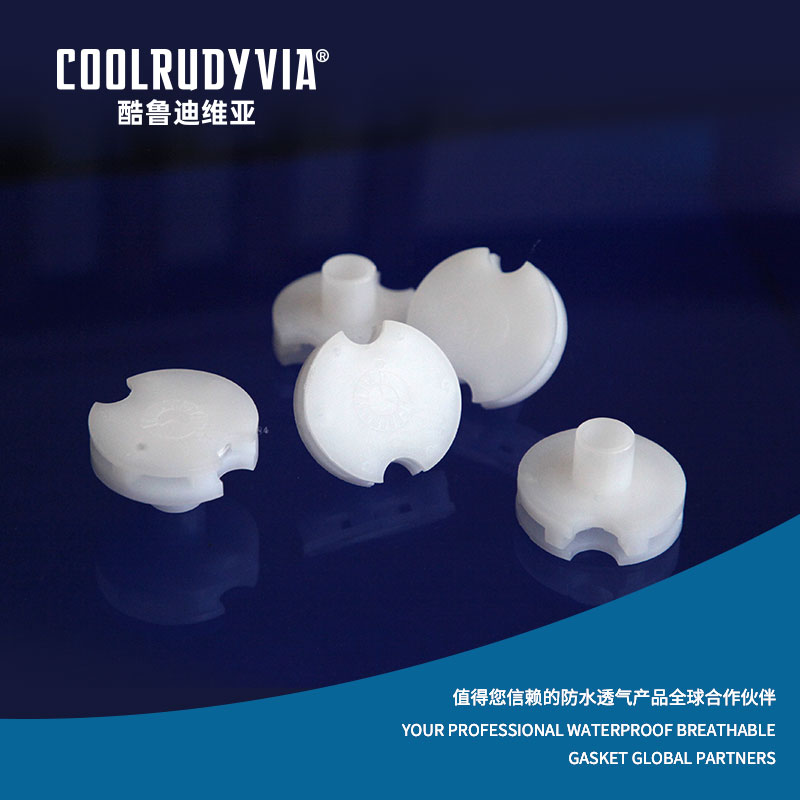

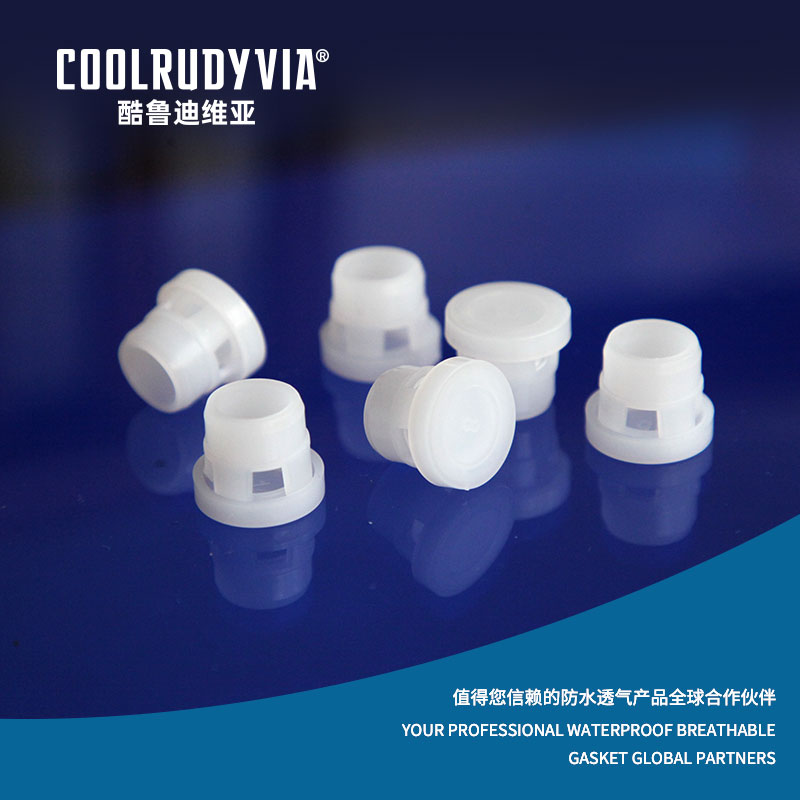

A waterproof breathable vent plug, also known as a breathable valve or waterproof plug, is a device that incorporates a microporous breathable membrane. Its primary function is to allow gases to pass through while blocking liquids (like water and oils) and solid contaminants (such as dust). The design of these vent plugs ensures that they prevent the ingress of moisture or debris into sensitive automotive components, while simultaneously allowing pressure equalization within sealed environments.

Core Working Principle

The technical core of a waterproof breathable vent plug is a membrane made from ePTFE (expanded polytetrafluoroethylene). This material boasts a microporous structure that selectively permits gas molecules (such as oxygen, nitrogen, and carbon dioxide) to pass through while blocking larger molecules like water and oil.

II. Factors to Consider When Choosing a Waterproof Breathable Vent Plug for Automotive Applications

When choosing a waterproof breathable vent plug for automotive use, several key factors must be considered to ensure optimal performance, reliability, and durability.

1. Material Selection: ePTFE Membranes

The material used in the vent plug's membrane is crucial. ePTFE is commonly used because of its hydrophobic properties, allowing it to repel water effectively. The microporous structure of ePTFE enables air to pass through freely, balancing the internal and external pressures within automotive components. The ability of ePTFE to block water and oils while allowing air molecules to move is essential for maintaining the performance and longevity of automotive parts exposed to varying temperatures and humidity.

2. Pressure Equalization

In automotive applications, pressure equalization is a critical function of the waterproof breathable vent plug. It ensures that components such as headlights or electronic sensors do not experience internal pressure buildups that can lead to leaks or ruptures. Proper pressure equalization helps prevent damage during extreme weather conditions or rapid temperature changes, such as those experienced when a vehicle moves from a cold to a hot environment.

The waterproof breathable vent plugs provided by Baonong are designed to prevent the formation of positive or negative pressure differentials, ensuring the safety and longevity of automotive parts.

3. IP Rating and Ingress Protection

The level of ingress protection (IP rating) that the vent plug provides is another important consideration. In automotive applications, the waterproof breathable vent plug should typically meet high IP standards, such as IP67 or IP68, ensuring that it effectively prevents the ingress of water, dust, and other contaminants. A higher IP rating indicates a more reliable product for use in environments where components are exposed to harsh conditions like rain, dust, or extreme temperatures.

4. Durability and Longevity

Automotive components often face challenging conditions, including vibrations, temperature fluctuations, and exposure to chemicals. Therefore, the waterproof breathable vent plug must be durable enough to withstand these conditions over the long term. The material's resistance to wear, fatigue, and environmental degradation is critical. High-quality vent plugs are typically made with materials that offer superior resistance to UV radiation, ozone, and other environmental factors.

5. Customization for Specific Automotive Needs

Different automotive components may require specialized vent plugs depending on their size, pressure requirements, and exposure conditions. Many manufacturers offer tailored waterproof breathable vent plugs, ensuring that the product is designed specifically for the unique needs of the automotive industry. Customization may include factors like size, airflow capacity, and specific IP ratings to meet the exact specifications of automotive applications.

Baonong offers customized solutions that cater to the specific requirements of automotive components, ensuring that each vent plug is optimally suited for its intended application.

III. Advantages of Waterproof Breathable Vent Plugs in Automotive Applications

1. Improved Sealing Performance

One of the primary benefits of using waterproof breathable vent plugs in automotive applications is the enhanced sealing performance. These vent plugs allow air to escape without letting harmful contaminants inside, maintaining the integrity of sensitive components like headlamps, electrical junctions, and sensors. This enhanced sealing helps maintain optimal performance throughout the lifespan of the vehicle.

2. Cost-Efficiency and Maintenance

By preventing internal pressure buildup and the ingress of contaminants, waterproof breathable vent plugs reduce the likelihood of costly damage and maintenance. Their ability to balance internal and external pressure means fewer failures, longer-lasting components, and reduced repair costs for automotive manufacturers and end-users alike.

3. Safety and Environmental Protection

In applications where sealed containers or components are exposed to high-pressure environments, using a waterproof breathable vent plug ensures that these components can function safely without the risk of rupture. This is especially important in automotive systems where safety is a top priority. Additionally, the vent plug's ability to prevent water ingress ensures that electrical components are protected from short circuits or corrosion.

IV. Installation and Maintenance of Waterproof Breathable Vent Plugs

1. Installation Considerations

The installation process for waterproof breathable vent plugs in automotive applications is relatively simple but requires careful attention to detail. The vent plug must be installed in the correct orientation, and its sealing properties should be tested to ensure that no contaminants can bypass the plug. It is also essential to ensure that the vent plug fits snugly within the designated space to avoid any leakage or improper performance.

Baonong's automated manufacturing processes ensure that the waterproof breathable vent plugs are precise and easy to install, providing consistent performance in automotive applications.

2. Routine Maintenance

While waterproof breathable vent plugs are designed for longevity, it is still important to perform routine checks to ensure their functionality. Over time, contaminants may accumulate on the exterior, or the vent plug may become damaged due to physical wear. Regular inspection of these components can help identify potential issues before they lead to failures.

V. Conclusion

Choosing the right waterproof breathable vent plug for automotive applications is essential for ensuring the safety, durability, and reliability of critical components. Factors such as material selection, pressure equalization, IP rating, and customization options should be carefully considered when selecting a vent plug for specific automotive needs. By understanding the core functions and benefits of these vent plugs, automotive manufacturers can enhance the performance and lifespan of their products while preventing costly damage and ensuring safety.

FAQs

1. What is the main function of a waterproof breathable vent plug in automotive applications?

The primary function of a waterproof breathable vent plug is to balance internal and external pressure while preventing the ingress of water, oil, and dust into sealed automotive components.

2. Can a waterproof breathable vent plug be used in outdoor automotive applications?

Yes, waterproof breathable vent plugs are designed to withstand harsh environmental conditions, including exposure to rain, dust, and extreme temperatures, making them suitable for outdoor automotive applications.

3. How does the ePTFE membrane in a waterproof breathable vent plug work?

The ePTFE membrane features a microporous structure that allows gas molecules to pass through while blocking larger particles like water droplets and oils, ensuring that only air can move freely through the vent plug.

English

English 中文简体

中文简体 Español

Español عربى

عربى