Why Has the Waterproof Vent Plug Become an Indispensable Key Component in Modern Industry?

Introduction: A Small Component with a Big Role

In numerous industrial fields such as automotive, electronics, and packaging, a seemingly insignificant small component is quietly determining the safety and reliability of products – the Waterproof Vent Plug. So, what problems does the waterproof and breathable vent plug solve? What is its core technology, and why is it becoming essential rather than optional?

I. How to Achieve Both Waterproofing and Breathability?

The Working Principle of the Waterproof Vent Plug

In sealed or semi-sealed structures, environmental temperature differences and pressure changes often create a so-called “breathing effect.” Without a proper pressure-balancing solution, moisture, dust, and even liquids may be drawn into the enclosure, causing corrosion, short circuits, or functional failure of internal components.

The core value of the waterproof and breathable vent plug lies in its ability to “breathe without letting water in.” It typically adopts high-performance waterproof and breathable membrane materials that allow air molecules to pass freely while effectively blocking water droplets and particulate matter.

Through this mechanism, the vent plug enables internal and external pressure balance while preventing water ingress and contamination, significantly improving the reliability and service life of the product.

II. What Are the Typical Application Scenarios of Waterproof Vent Plugs?

With increasing demands for precision, durability, and safety, the application scope of waterproof vent plugs continues to expand across multiple industries:

Automotive Industry

Automotive headlights, electronic control units, battery packs, and other components must operate stably over long periods in harsh environments involving vibration, temperature fluctuations, and moisture.

Packaging Industry

Beverage bottles and pesticide packaging require controlled gas release during transportation and storage while strictly preventing liquid leakage and external contamination.

Electronics and Industrial Equipment

Outdoor electronic devices, sensors, and industrial enclosures must withstand rain, humidity, dust, and rapid temperature changes without compromising performance.

In these scenarios, waterproof vent plugs have gradually evolved from a “nice-to-have” component into a truly essential functional part.

III. What Key Indicators Define a High-Quality Waterproof Vent Plug?

Faced with a wide variety of products on the market, truly high-quality waterproof vent plugs are usually distinguished by the following critical factors:

• Stable waterproof rating and consistent breathability performance

• Excellent resistance to aging and chemical exposure

• High adaptability in structural design and strong customization capability

• Reliable batch consistency and proven long-term performance

These indicators not only reflect the quality of the product itself but also reveal the technical expertise, manufacturing experience, and quality management system of the supplier behind it.

IV. Why Are More and More Customers Choosing Changzhou Baonong?

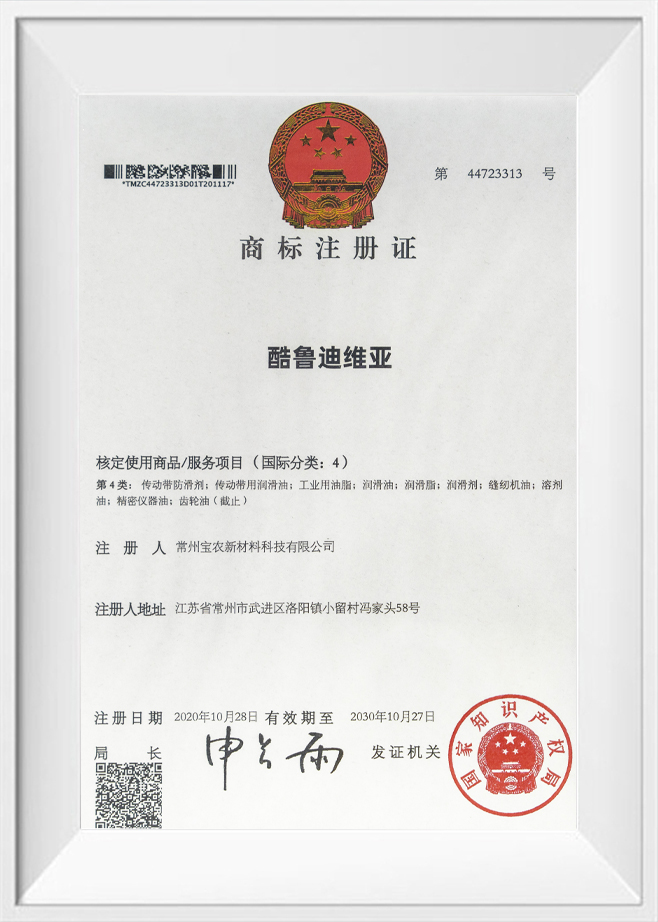

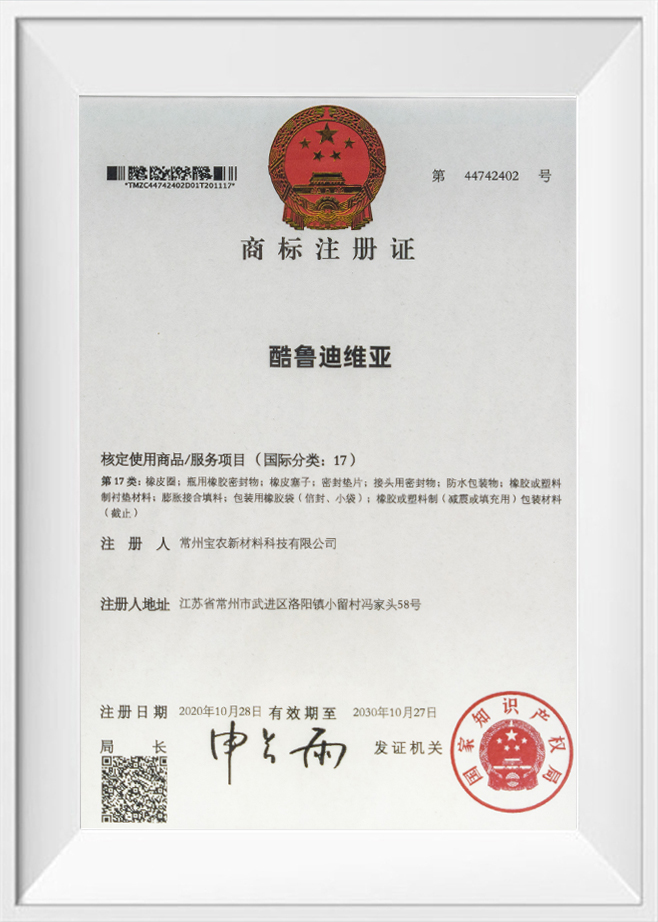

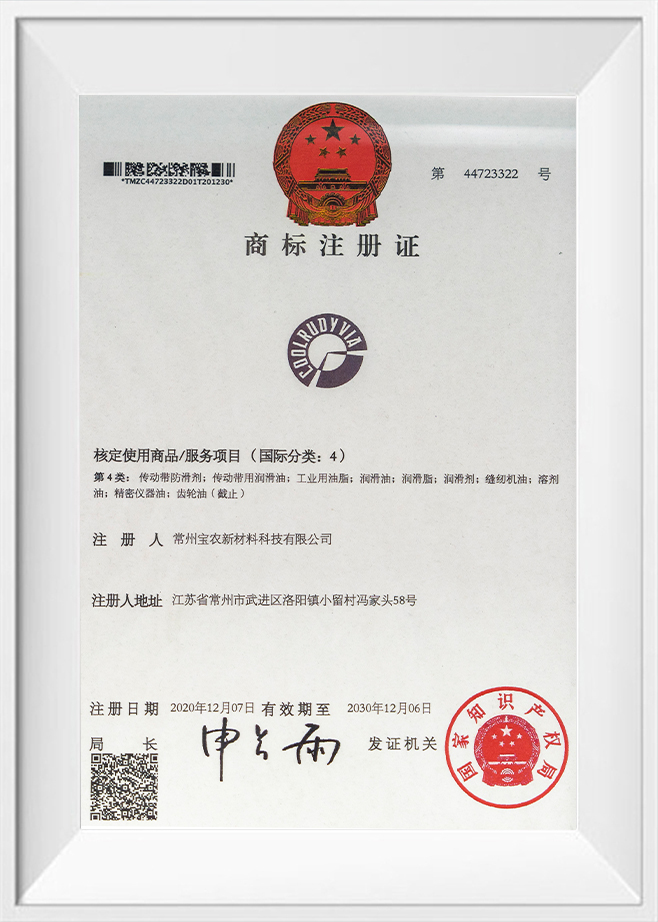

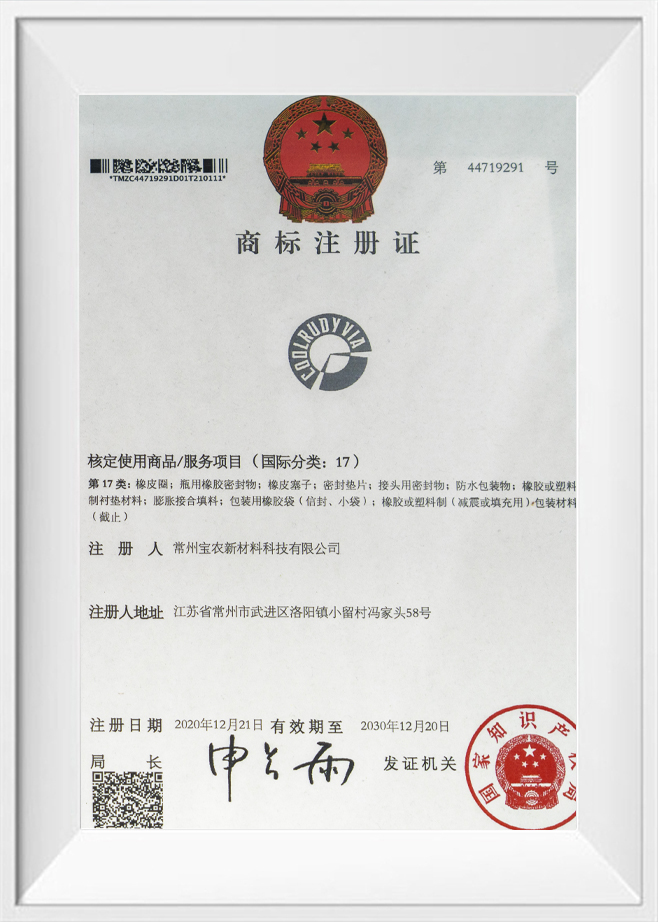

As a professional China Waterproof Vent Plug Manufacturer and Custom Air Vent Plug Factory, Changzhou Baonong New Material Technology Co., Ltd. has been rooted in Changzhou, known as the “Dragon City,” since its establishment. The company closely follows industry development trends and focuses on the continuous innovation of waterproof and breathable technology.

After eight years of steady development, Baonong New Material has established itself as one of the few standardized, modern, and high-quality integrated manufacturers in the industry:

• Over 6,000 square meters of standardized industrial workshops

• Integrated capabilities covering design, R&D, production, and sales

• Specialized in waterproof and breathable gaskets, plugs, and vent covers

• Products widely used in automotive headlights, beverage packaging, pesticide packaging, and more

The company’s core advantage lies in its ability to truly achieve “breathability without water ingress,” ensuring safety and reliability during both use and transportation.

V. Intelligent Manufacturing and Rigorous Quality Control

How Is the Reliability of Every Vent Plug Ensured?

Quality is not a slogan, but a complete and systematic process.

Changzhou Baonong New Material Technology is equipped with more than 90 sets of automated production and testing equipment with independent intellectual property rights. These systems are characterized by high speed, high precision, excellent stability, and strong reliability.

This advanced manufacturing capability allows Baonong to deliver professional waterproof vent plug solutions to customers in a fast, stable, and efficient manner while maintaining consistently high quality.

More importantly, every waterproof vent plug must pass a strict dual inspection process:

• Automated equipment performance testing

• Manual secondary inspection

This dual-quality-control mechanism ensures stable and reliable product performance, helping customers build long-term trust with end users in their respective markets.

VI. Where Is the Future of Waterproof Vent Plugs Headed?

Driven by the rapid growth of new energy vehicles, smart devices, and high-end packaging solutions, waterproof vent plugs are continuously evolving toward:

• Higher performance standards

• Stronger environmental adaptability

• Greater levels of customization

In this competitive landscape, manufacturers with strong R&D capabilities, advanced automated production, and strict quality control systems will gain a clear advantage.

Changzhou Baonong New Material Technology Co., Ltd. is firmly positioned within this trend, consistently creating long-term value for global customers through technological innovation and customer-oriented service.

FAQ (Frequently Asked Questions)

Q1: Can waterproof vent plugs be customized?

A: Yes. Baonong New Material supports customized development based on customers’ structural designs, application environments, and specific performance requirements.

Q2: Can waterproof vent plugs be used in high-humidity or large temperature-difference environments?

A: Yes. High-quality waterproof and breathable membrane materials are specifically designed to adapt to high humidity and frequent temperature fluctuations.

Q3: How can I determine whether a waterproof vent plug has stable quality?

A: It is recommended to focus on the manufacturer’s automation level, inspection mechanisms, and real-world application cases rather than relying on a single performance parameter.

Q4: Which industries are Baonong’s products suitable for?

A: Baonong’s waterproof vent plug products are widely used in automotive, electronics, industrial equipment, beverage packaging, pesticide packaging, and many other industries.

English

English 中文简体

中文简体 Español

Español عربى

عربى