What are the advantages of using stainless steel vent plugs compared to other materials (such as aluminum alloy or plastic)?

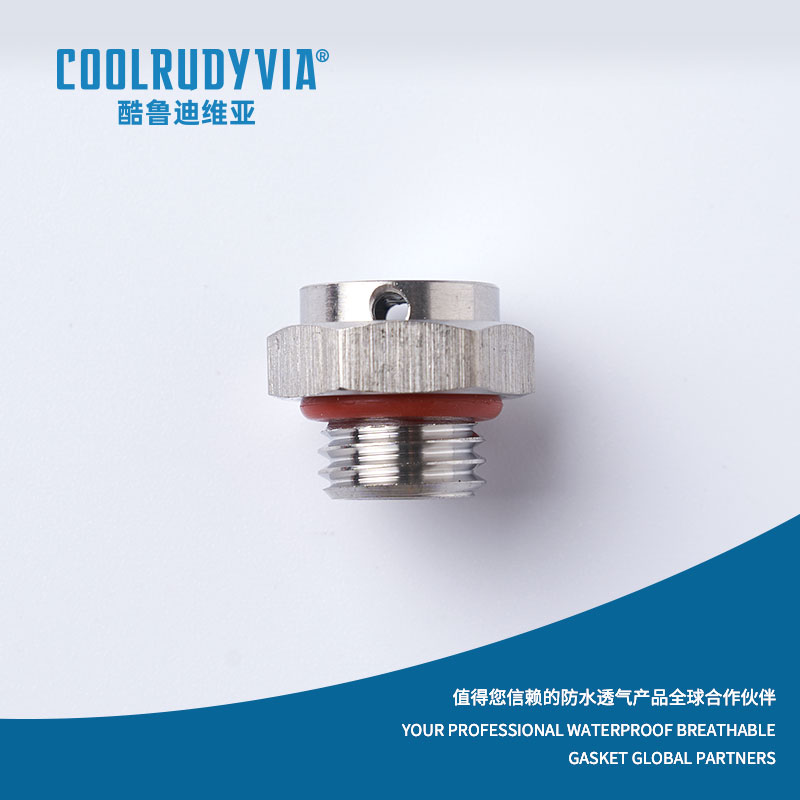

Vent plugs are vital components in a wide array of industries, from automotive and electronics to packaging and industrial applications. Made from materials like stainless steel vent plug, plastic vent plug, and aluminum alloy vent plug, these devices help regulate pressure, prevent contamination, and maintain the integrity of the equipment they protect. Understanding the advantages of using stainless steel vent plugs over alternatives like plastic vent plugs and aluminum alloy vent plugs is essential when selecting the appropriate material for specific applications.

Changzhou Baonong New Material Technology Co., Ltd., with its deep roots in the development trends and innovation of the industry, specializes in high-quality waterproof and breathable membrane products. Their commitment to producing top-tier vent plugs for various industries, such as automotive, beverage packaging, and electronics, ensures their products meet rigorous standards. With over 90 sets of automated equipment, their efficient production capabilities and strict quality control help deliver reliable, long-lasting solutions.

I. The Importance of Vent Plugs in Modern Applications

Vent plugs are essential to ensuring safe and efficient operation across numerous devices. Their core function is to regulate pressure, prevent contamination, and safeguard internal components. These products are widely used in automotive, outdoor electronics, and packaging, with materials like stainless steel, plastic, and aluminum alloy being the most common choices. The performance of these vent plugs heavily depends on the material used, making the choice of material crucial for specific environments.

For companies like Changzhou Baonong New Material Technology Co., Ltd., which has built its reputation on providing quality vent plugs for applications such as automotive headlamps and beverage packaging, understanding these material advantages allows them to meet diverse customer needs effectively.

II. Material Properties of Stainless Steel, Plastic, and Aluminum Alloy

1. Stainless Steel Vent Plug

Stainless steel vent plugs stand out due to their corrosion resistance, mechanical strength, and durability in extreme environments. Made from high-grade stainless steel alloys such as 304 and 316L, these vent plugs can withstand exposure to harsh conditions, including high temperatures and chemical corrosion, making them ideal for demanding applications like automotive, industrial machinery, and outdoor electronics.

Advantages of Stainless Steel Vent Plugs:

- Excellent corrosion resistance: Stainless steel’s resilience to rust, corrosion, and environmental exposure ensures long-term performance, even in coastal or industrial environments.

- High-temperature tolerance: Stainless steel vent plugs can operate in extreme temperature ranges, from -40°C to +150°C or more, making them suitable for a variety of high-heat applications.

- Durability and strength: Stainless steel offers superior mechanical strength, ensuring reliable performance over an extended service life.

2. Plastic Vent Plug

Plastic vent plugs, typically made from materials such as PA6 or PA66, are a more lightweight and cost-effective option. While they offer convenience for low-cost and lightweight applications, they are not as durable or temperature-resistant as stainless steel. As such, they are often used in less demanding environments such as consumer packaging or electronics, where high strength and temperature resistance are less critical.

Advantages of Plastic Vent Plugs:

- Cost-effective: Plastic vent plugs are generally much cheaper than metal options, making them ideal for applications with tight budgets.

- Lightweight: Their lightweight nature makes them perfect for applications where weight is a crucial factor, such as in beverage bottles or consumer electronics.

- Customizability: Plastic vent plugs can be easily molded into a wide range of shapes and sizes, providing flexibility in product design.

However, plastic vent plugs come with limitations, particularly in terms of temperature resistance and long-term durability, which can lead to failure under extreme conditions.

3. Aluminum Alloy Vent Plug

Aluminum alloy vent plugs are often chosen for their balance of strength, weight, and cost. While not as resistant to corrosion as stainless steel, aluminum alloy provides a reliable option for industries where weight reduction is critical, such as automotive and electronics.

Advantages of Aluminum Alloy Vent Plugs:

- Lightweight: Aluminum alloy is much lighter than stainless steel, which is advantageous in applications where weight is a key consideration.

- Good corrosion resistance: Although not as corrosion-resistant as stainless steel, aluminum alloys offer reasonable protection against rust and environmental factors.

- Moderate cost: Aluminum alloy vent plugs strike a balance between cost and performance, making them suitable for a wide range of industrial applications.

Despite these advantages, aluminum alloy vent plugs may not perform as well as stainless steel in extremely corrosive or high-temperature environments.

III. Performance Comparison: Stainless Steel vs. Plastic vs. Aluminum Alloy Vent Plugs

When evaluating the performance of stainless steel vent plugs, plastic vent plugs, and aluminum alloy vent plugs, several key factors come into play, including corrosion resistance, temperature tolerance, durability, and cost. Each material has its strengths and weaknesses, and the right choice depends on the specific requirements of the application.

| Material |

Corrosion Resistance |

Temperature Range |

Durability |

Cost |

| Stainless Steel |

Excellent |

-40°C to +150°C (or higher) |

High (long lifespan) |

Higher |

| Plastic (PA6/PA66) |

Low to Moderate |

-20°C to +80°C |

Moderate |

Low |

| Aluminum Alloy |

Moderate |

-40°C to +120°C |

Moderate to High |

Moderate |

1. Corrosion Resistance

Stainless steel vent plugs provide exceptional protection against corrosion, making them the material of choice for marine, automotive, and industrial applications. Plastic vent plugs, on the other hand, offer limited protection against chemicals and environmental factors, while aluminum alloy vent plugs offer moderate corrosion resistance, making them suitable for general industrial use.

2. Temperature Range

Stainless steel vent plugs are ideal for applications requiring high temperature resistance. These vent plugs can maintain performance in temperatures ranging from -40°C to +150°C, ensuring they work reliably in both cold and hot environments. Plastic vent plugs have a limited temperature range, often failing at higher temperatures, while aluminum alloy vent plugs are suitable for moderate temperature conditions but not extreme heat.

3. Durability

The robustness of stainless steel vent plugs ensures that they are highly durable and resistant to impacts, wear, and corrosion. This makes them ideal for long-term use in demanding environments. Plastic vent plugs are more susceptible to wear and tear, which can lead to premature failure, while aluminum alloy vent plugs are relatively durable but less resistant to impacts compared to stainless steel.

4. Cost

Plastic vent plugs are the most affordable option, making them suitable for applications with tight budgets. Aluminum alloy vent plugs are more cost-effective than stainless steel but offer a balance between price and performance. Stainless steel vent plugs are more expensive but provide superior performance and longevity, making them worth the investment for critical applications.

IV. Applications of Vent Plugs in Different Industries

Automotive Industry

In automotive applications, stainless steel vent plugs are widely used in headlamps, fuel systems, and engine compartments, where their high resistance to temperature, pressure, and environmental exposure ensures long-term reliability. Changzhou Baonong New Material Technology Co., Ltd. provides venting solutions that meet the stringent demands of the automotive industry, ensuring the safety and durability of their products.

Outdoor Electronics

For outdoor electronics, plastic vent plugs are commonly used, especially for lightweight and cost-sensitive applications. However, in more rugged environments, stainless steel and aluminum alloy vent plugs offer greater protection against the elements.

Packaging Industry

In the packaging sector, plastic vent plugs are popular due to their low cost and suitability for consumer products like beverage bottles. However, in industrial packaging, especially for chemicals or pharmaceuticals, stainless steel vent plugs are often used for their superior durability and corrosion resistance.

V. Conclusion

Choosing the right material for vent plugs—whether stainless steel, plastic, or aluminum alloy—depends on factors such as environmental conditions, cost, and performance requirements. Stainless steel vent plugs offer unmatched durability, corrosion resistance, and high-temperature performance, making them the preferred choice for critical applications in automotive, outdoor electronics, and industrial machinery. While plastic vent plugs and aluminum alloy vent plugs offer cost-effective alternatives, they may not provide the same level of performance and reliability in demanding environments. Companies like Changzhou Baonong New Material Technology Co., Ltd. continue to lead the way in providing high-quality vent plugs that meet diverse industry needs.

VI. FAQs

What is the difference between stainless steel vent plugs and aluminum alloy vent plugs?

Stainless steel vent plugs provide superior corrosion resistance and can withstand higher temperatures and pressure differences than aluminum alloy vent plugs. Aluminum alloy vent plugs, however, are lighter and more cost-effective.

Are plastic vent plugs suitable for high-temperature applications?

No, plastic vent plugs are not ideal for high-temperature applications. They are more suitable for low to moderate temperature environments.

How do I choose the right material for a vent plug?

The choice of material depends on factors such as temperature range, corrosion resistance, durability, and cost. For high-performance applications, stainless steel vent plugs are the best choice, while plastic vent plugs are ideal for cost-sensitive applications.

Can stainless steel vent plugs be used in marine environments?

Yes, stainless steel vent plugs are highly resistant to corrosion and can withstand the harsh conditions typically found in marine environments.

English

English 中文简体

中文简体 Español

Español عربى

عربى