Why are Stainless Steel Vent Plugs becoming the new standard for industrial sealing and safety?

Introduction: When safety, stability, and reliability become necessities

In modern industrial and packaging fields, safety, stability, and reliability are no longer just slogans, but fundamental requirements for product design. Among many seemingly insignificant yet crucial components, the stainless steel vent plug is gradually taking center stage.

What exactly is a stainless steel vent plug?

A Stainless Steel Vent Plug is a functional component primarily made of stainless steel, with an integrated waterproof and breathable membrane. Its core function is to:

- Balance internal and external air pressure

- Effectively block the entry of moisture, dust, and other pollutants

In sealed or semi-sealed systems, temperature changes, gas reactions, or environmental changes during transportation can cause internal pressure fluctuations. If the pressure cannot be released in time, it can lead to seal failure, deformation, leakage, or even safety accidents. The stainless steel vent plug is designed to solve this "invisible but dangerous" problem.

The technical secret of “breathable but waterproof”

The true technical core of the stainless steel vent plug is not just the metal body, but the internal waterproof and breathable membrane. These membrane materials usually have a microporous structure, with pore sizes much smaller than water droplets but larger than gas molecules:

- Gases can pass freely, achieving pressure balance

- Liquid water is completely blocked, ensuring internal dryness

- Excellent resistance to chemical corrosion and aging

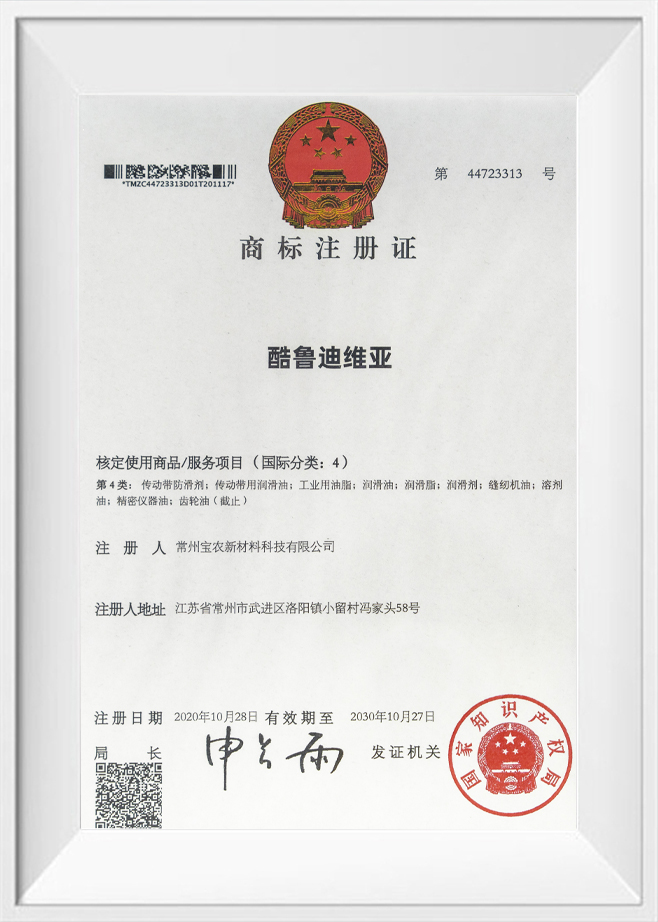

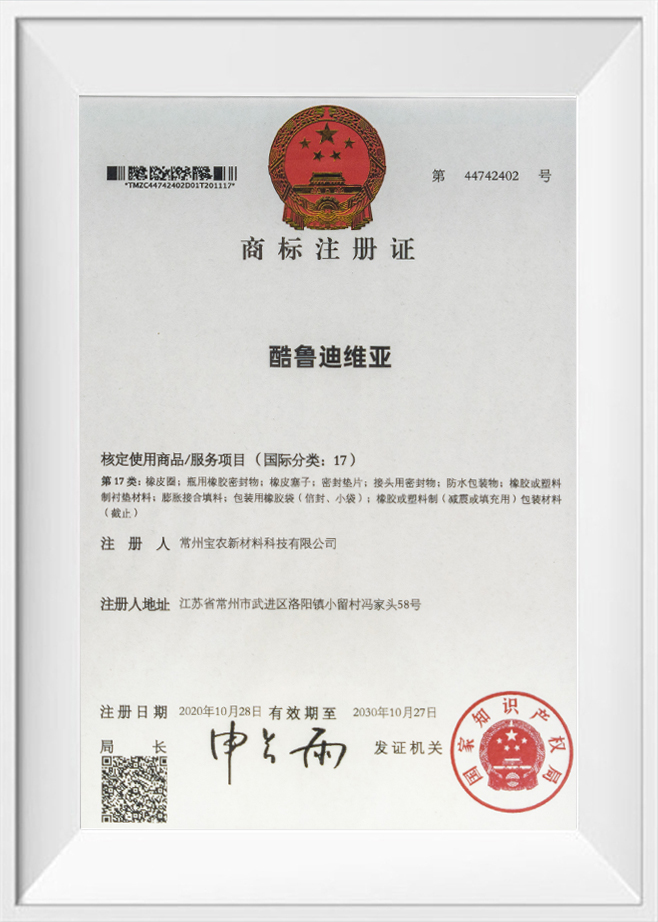

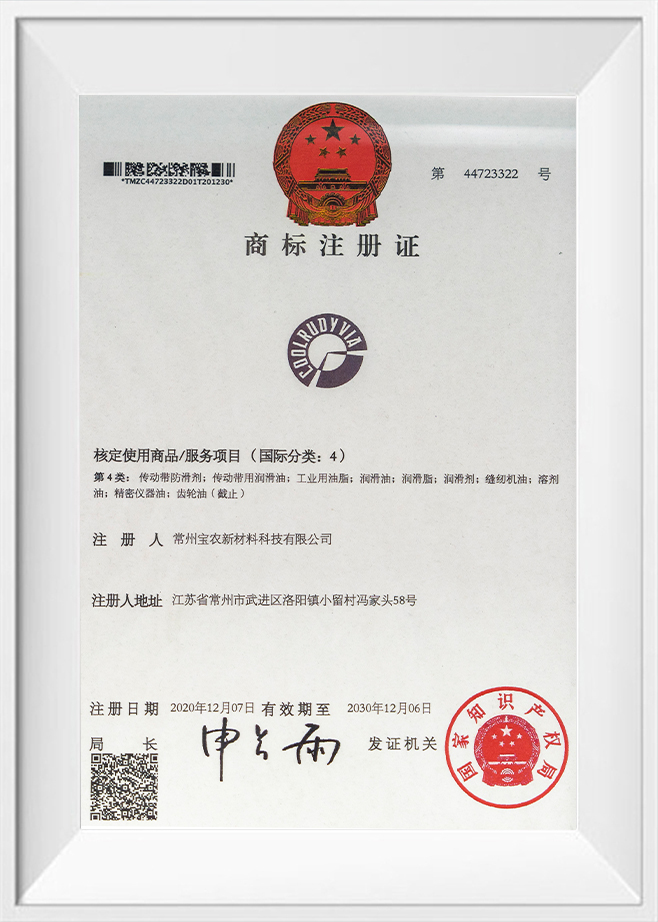

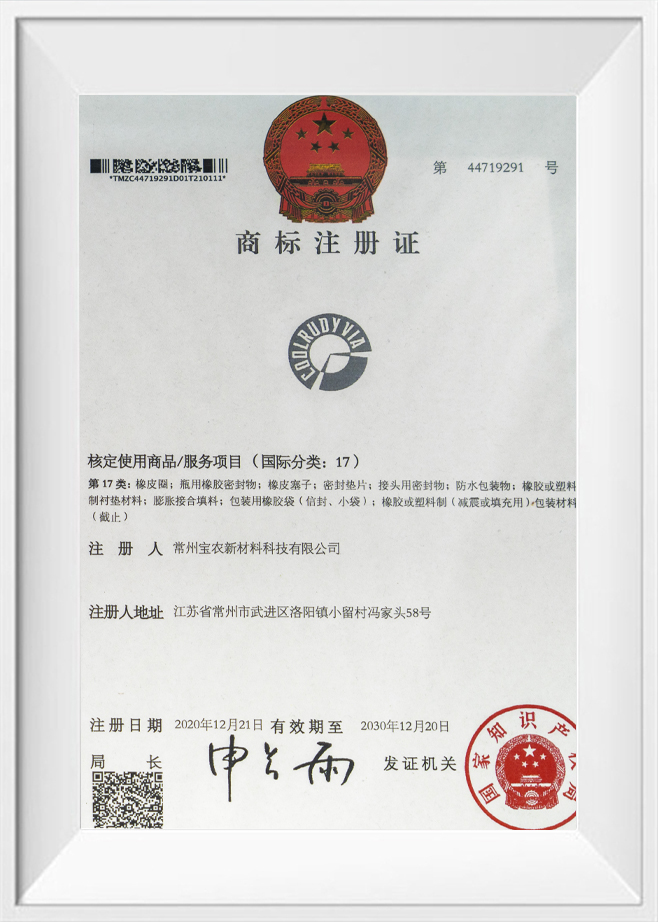

Changzhou Baonong New Material Technology Co., Ltd. has focused on the research, development, and production of waterproof and breathable membranes and their components for many years. Through continuous innovation in membrane material selection, structural matching, and overall sealing design, Baonong ensures that stainless steel vent plugs maintain stable and reliable performance even under complex working conditions.

Why choose stainless steel?

Compared with plastic or ordinary metal materials, stainless steel vent plugs offer clear advantages:

- Stronger mechanical strength: Suitable for high-pressure or vibration environments

- Excellent corrosion resistance: Performs reliably in chemical, humid, or outdoor environments

- Longer service life: Reduces replacement frequency and overall maintenance costs

- Professional appearance and texture: Ideal for high-end and quality-oriented products

Thanks to these benefits, stainless steel vent plugs are increasingly adopted in automotive parts, industrial equipment, and high-end packaging applications.

Which industries are they widely used in?

With the continuous upgrading of industrial standards, stainless steel vent plugs are no longer limited to a single field. Typical application industries include:

- Automotive industry: Headlamps, sensors, electronic control units (ECUs)

- Packaging industry: Beverage bottles, pesticide and chemical containers

- Industrial equipment: Outdoor electrical devices, precision instrument housings

- New energy and electronics: Enclosures requiring both pressure equalization and high protection levels

All these application scenarios share a common requirement: effective sealing protection without completely sealing off the internal pressure.

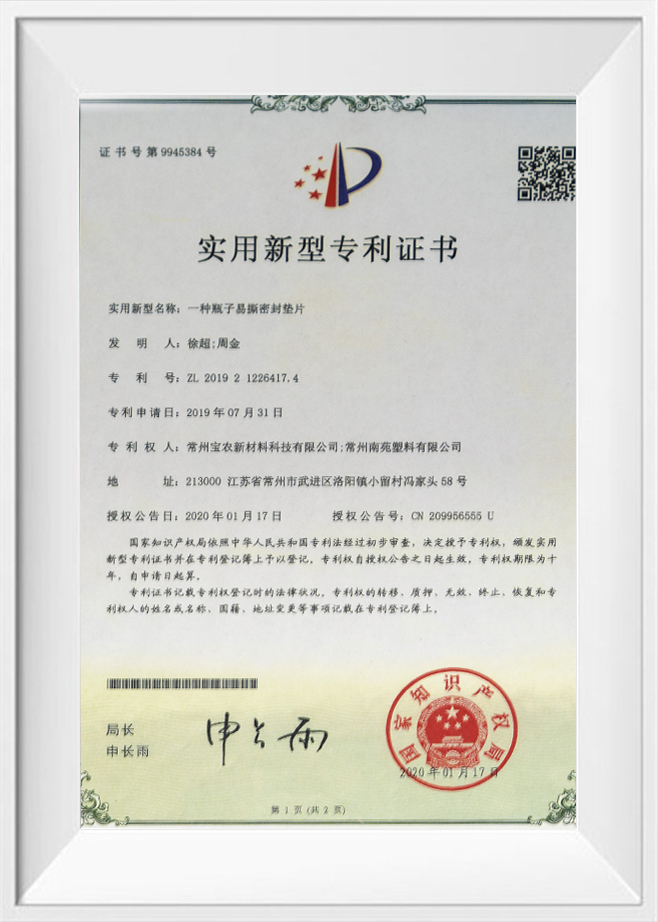

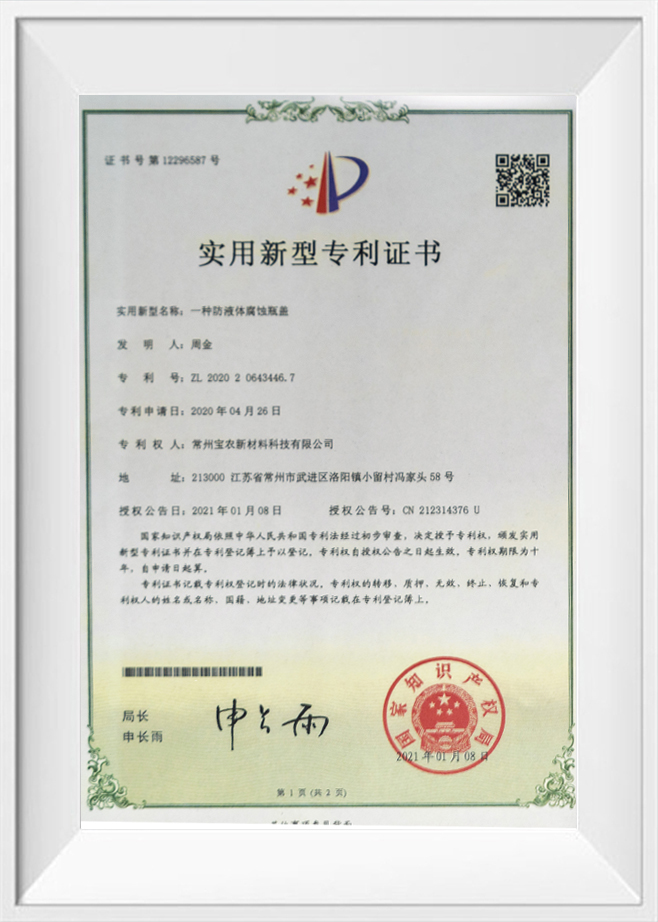

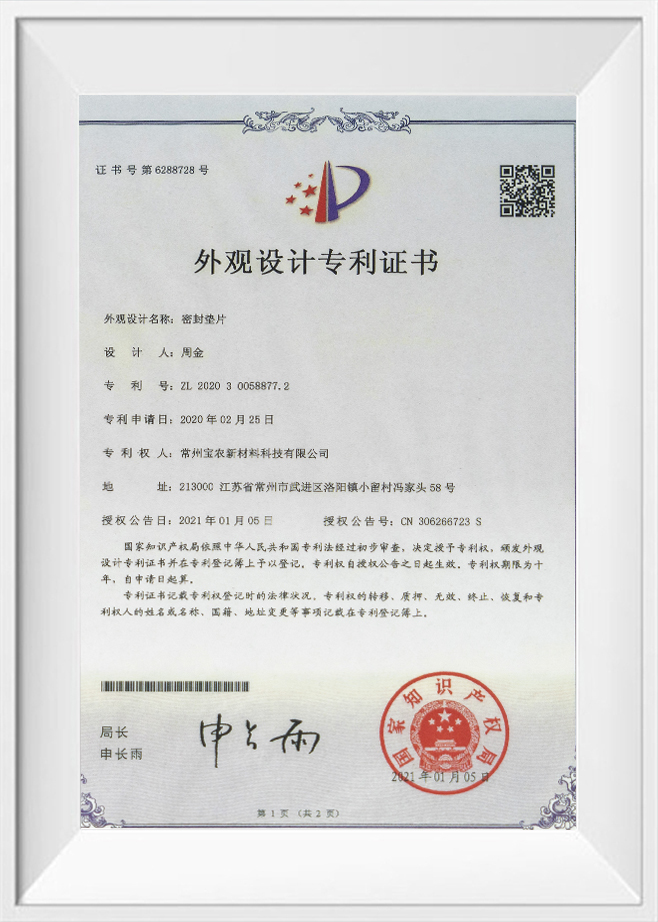

The strength behind professional manufacturing

As a Chinese manufacturer of stainless steel vent plugs and a custom breather plug factory, Changzhou Baonong New Material Technology Co., Ltd. has been rooted in Changzhou, known as the “Dragon City,” since its establishment. The company closely follows industry trends and remains committed to innovation and customer-focused service.

- Standardized industrial plant covering more than 6,000 square meters

- More than 90 sets of automated equipment with independent intellectual property rights

- An integrated system covering design, R&D, production, and sales

- Dual quality inspection: automated testing combined with manual re-inspection

This long-term dedication to manufacturing details and quality stability allows Baonong’s products to consistently help customers gain trust and recognition in the end market.

Customization is becoming a new trend

Different industries and products have varying requirements for ventilation volume, protection level, and structural dimensions. Standard components often fail to meet all real-world needs, making customized stainless steel vent plugs an increasingly popular solution.

Relying on a mature R&D team and a flexible production system, Changzhou Baonong New Material Technology Co., Ltd. can provide:

- Different thread types and installation methods

- Multiple ventilation volumes and protection levels

- Material combination solutions tailored to specific operating environments

This approach transforms vent plugs from simple “accessories” into an integral part of overall product design.

FAQ – Frequently Asked Questions

Q1: Are stainless steel vent plugs always better than plastic ones?

A: Not in all cases. However, stainless steel offers clear advantages in high-temperature, high-pressure, corrosive, or high-reliability applications.

Q2: Will a vent plug affect the sealing level?

A: With proper selection and installation, high-quality vent plugs can achieve IP67 or even higher protection levels while still allowing effective ventilation.

Q3: Can vent plugs be customized according to product structure?

A: Yes. Professional manufacturers can provide customized solutions for size, structure, and performance parameters.

Q4: What is the typical lifespan of a stainless steel vent plug?

A: Depending on the operating environment and material selection, high-quality stainless steel vent plugs can usually last as long as the product itself.

In an era where safety, reliability, and precision are essential, stainless steel vent plugs are no longer optional components but a key guarantee of product quality. Choosing a professional manufacturing partner often determines a product’s long-term competitiveness in the market.

English

English 中文简体

中文简体 Español

Español عربى

عربى